In the realm of manufacturing and engineering, the evolution of machinery has played a pivotal role in shaping the industry’s future. Among these revolutionary innovations, the CNC lathe machine stands out as a cornerstone, empowering precision, efficiency, and versatility in metalworking. Understanding what is a CNC lathe machine reveals its significance in modern manufacturing processes and highlights why it has become an indispensable tool in workshops worldwide. This guide aims to demystify the complexities surrounding CNC lathe machines, providing insight into their operation, capabilities, and the advantages they bring to the table.

As we delve deeper into this in-depth guide, we will explore the various facets of CNC lathe machines, starting with a brief history to appreciate their evolution and technological advancements. We will break down the core components that constitute a CNC lathe machine, explaining how each plays a critical role in its functionality. Following that, an overview of how CNC lathe machines work will set the foundation for understanding the types of operations these versatile machines can perform. We will also examine the different types of CNC lathe machines available, the common operations they are used for, and the industries that rely heavily on this technology. Lastly, we will highlight the benefits of using CNC lathe machines, demonstrating their impact on productivity and precision. Through this journey, we aim to provide a comprehensive understanding of what is a CNC lathe machine and why it remains a pivotal tool in manufacturing.

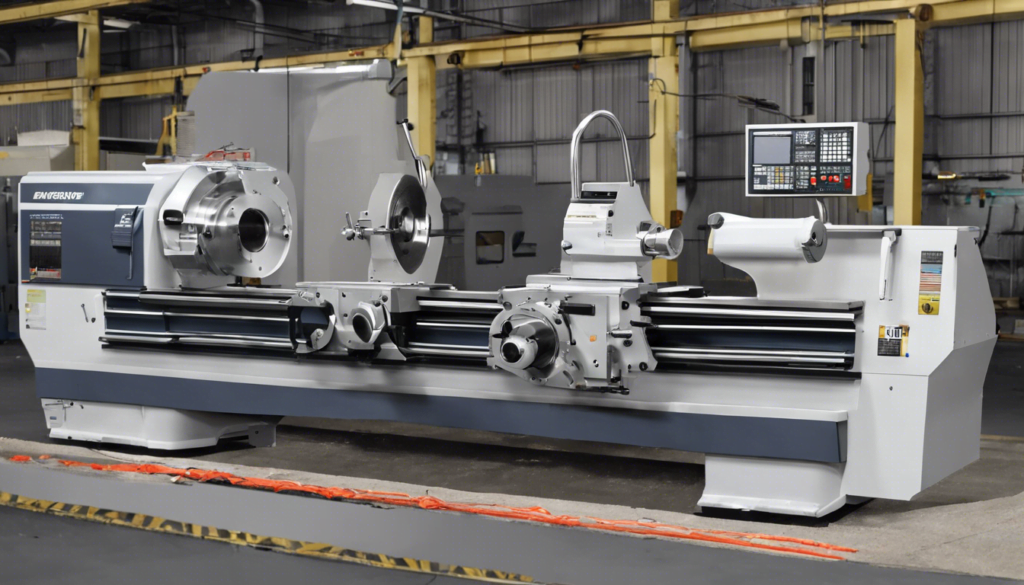

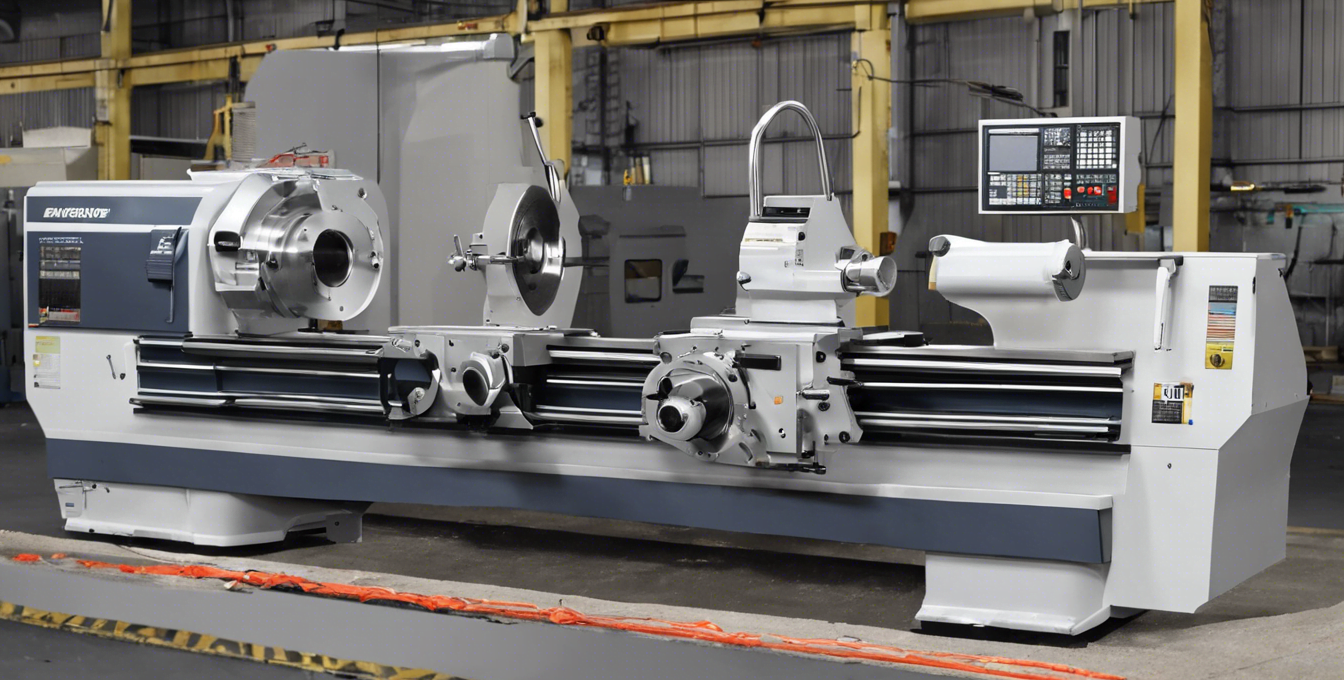

What is a CNC Lathe Machine?

A CNC lathe, also known as a CNC turning machine, is an advanced piece of machinery that fundamentally changes how materials are shaped and manufactured. At its core, the CNC lathe spins material around a central spindle while a fixed cutting tool shapes the material. This process is not manually controlled but is driven by coded instructions programmed into a computer. This automation allows for precise cuts and detailed machining that manual operations cannot achieve.

The design of a CNC lathe includes a swing, which refers to the largest diameter of the material that can rotate over the machine bed. This swing enables the CNC lathe to perform various operations such as cutting, sanding, and drilling. The bed length and the distance between the headstock and tailstock are also crucial specifications, affecting the size of the material that can be machined.

One of the key components of a CNC lathe is the headstock, which houses the drive motor and powers the spindle. The spindle, in turn, is attached to either a chuck or a collet, which secures the workpiece during the turning process. Chucks are suitable for gripping larger parts, while collets are used for smaller items, providing a firmer grip and greater precision.

Opposite the headstock is the tailstock, designed to support longer workpieces during machining. It is mounted directly to the bed and can apply hydraulic force to support the workpiece securely. However, the tailstock must be retracted or removed for operations like face turning, where it might obstruct the machining process.

The bed of the CNC lathe serves as a foundation, supporting all other components. It is typically made from a heat-treated material to withstand the stresses of machining. Over this bed slides the carriage, which holds the cutting tools. The carriage moves along the bed, guided by rails or tracks, allowing the cutting tools to interact with the rotating workpiece.

CNC lathes can vary in complexity from simple 2-axis machines with a fixed tool turret to more advanced multi-axis systems capable of handling complex, intricate shapes. Regardless of the type, CNC lathes are integral to modern manufacturing, offering unparalleled precision and efficiency in machining a wide range of materials, including metals, plastics, and woods. This versatility and capability make the CNC lathe a cornerstone tool in many industries, revolutionizing traditional lathe operations through advanced computer numerical control.

History of CNC Lathe Machines

The origins of CNC (Computer Numerical Control) lathe machines trace back to the pioneering developments in the mid-20th century. The journey began with the invention of Numerical Control (NC) machines, which were the precursors to today’s advanced CNC systems.

Early Innovations and Developments

The concept of numerical control was first developed in 1949 by John T. Parsons alongside the Massachusetts Institute of Technology (MIT) as part of an Air Force research project. The initial focus was to create motorized axes that could produce complex parts such as helicopter blades and aircraft skins. This project laid the groundwork for the development of more sophisticated machines.

By 1952, the collaboration between Richard Kegg and MIT led to the creation of the Cincinnati Milacron Hydrotel, the first CNC machine which marked a significant advancement with its ability to operate on pre-programmed instructions using paper tape. This machine was a 28-inch vertical-spindle contour milling machine, which was a breakthrough in machining technology.

Transition from NC to CNC

While NC machines utilized punch cards and later magnetic tape for programming, they did not involve computers in their operation, functioning similarly to automatic pianos of the past. However, the transition to CNC began with the integration of computers, which allowed for more complex and precise control over the machining processes.

The first true CNC machine was developed in 1952 by a team at MIT, following the earlier NC machine prototypes. These CNC machines utilized a simple programming language known as G-Code, which provided instructions on tool movement and operation, revolutionizing the machining process by allowing for the creation of intricate and precise components that were challenging with manual controls.

Advancements and Recognition

The evolution of CNC technology continued rapidly through the 1960s and 1970s as digital technologies emerged, making the machines more efficient and automated. John Parsons, often recognized as the father of the second industrial revolution, received numerous accolades for his contributions, including the Joseph Marie Jacquard Memorial Award.

By the late 1970s, CNC technology had become the standard in large-volume manufacturing, thanks to the development of Computer Aided Design (CAD) systems. These systems allowed for the creation of detailed 3D models that could be directly translated into G-Code, further simplifying and speeding up the manufacturing process.

Modern CNC Machining

Today, CNC lathe machines are integral to manufacturing industries, capable of producing precise and repetitive parts with minimal human intervention. The continuous improvements in CNC technology have led to the development of multi-axis machines capable of handling complex shapes and designs, significantly enhancing productivity and reducing labor costs.

This historical progression from manual machining to the sophisticated CNC lathe machines of today highlights the incredible advancements in manufacturing technology, driven by the need for precision, efficiency, and automation.

Core Components of a CNC Lathe Machine

Main Spindle

The main spindle, nestled within the headstock, is the rotational axis pivotal for operations like turning and facing. It is designed for adaptability, accommodating diverse attachments to ensure secure workpiece grips. Precision bearings support the spindle, maintaining its alignment with the headstock and facilitating movement with minimal friction. This impeccable positioning is crucial, as even the slightest misalignment or vibration can jeopardize machining precision. The spindle’s speed and direction can be adjusted based on the machining requirements, making it a versatile component in CNC lathe operations.

Guide Way

Situated atop the bed, the guideways are meticulously crafted channels that direct the consistent linear motion of the carriage. Their precision-focused design and alignment are instrumental in dictating the exact trajectory of the carriage, cross slide, and compound rest. The smoothness and accuracy of the CNC machining process are contingent on the guideways’ capacity to mitigate friction while maintaining perfect alignment.

Chuck

The chuck is a critical component at the heart of CNC lathe operations. It grips, secures, and holds the workpiece in place during the machining process, allowing for accurate and consistent operations. The chuck ensures the workpiece remains stationary while the tool moves, facilitating various tasks like drilling, turning, or milling. Various types of chucks are used in CNC lathes, including three-jaw (universal) chucks, four-jaw chucks, and collet chucks, each providing different advantages in terms of grip and precision.

Headstock

The headstock is the power epicenter of a CNC lathe, housing crucial mechanisms that channel motor power to the central spindle. This component is responsible for generating the requisite power, with the spindle translating this into pinpointed rotational action. The headstock’s robust design is essential for the machine’s ability to handle varied machining demands with unmatched accuracy and efficiency.

Tool Turret

The tool turret stands out primarily for its ability to revolutionize the machine tool change process. Unlike traditional lathes that relied on manual tool exchanges, the tool turret in CNC machines permits several machine tools to be pre-configured, enabling on-the-fly adjustments during machining tasks. This feature dramatically reduces idle periods and facilitates the effortless crafting of intricate components through varied procedures. Each tool in the turret can be rotated into the cutting position automatically, enhancing the machine’s operational efficiency.

How Does a CNC Lathe Machine Work?

Understanding how a CNC lathe machine operates involves several critical stages, from design to final quality checks. Each phase is essential for ensuring the machine functions accurately and efficiently, producing parts that meet exact specifications.

Design Phase

The initial step in CNC lathe machining involves a meticulous process of identifying and finalizing the specific CNC turning machining content required for the given part. This encompasses a comprehensive evaluation of the part’s design and specifications to determine the most suitable machining approach. The analysis includes scrutinizing dimensioning methods, contour geometry features, accuracy, and technical requirements of the part drawings. The rationality analysis of part structure and machining requirements is vital, along with selecting appropriate process benchmarks.

Programming

Programming is a cornerstone of CNC lathe operations. G-code, a standardized language used in CNC machines, plays a pivotal role here. It consists of a series of commands that control the movement and operation of the machine, dictating the precise instructions for cutting, shaping, and forming parts. Familiarizing oneself with key terms like feed rate and spindle speed is crucial. These terms describe how fast the cutting tool moves along the workpiece and how fast the workpiece rotates, respectively. Effective CNC programming also involves understanding the various operations such as facing, turning, and threading, each requiring specific G-code instructions.

Setup

Before actual machining, setting up the CNC lathe is critical. This includes installing and adjusting the correct tooling, which determines the type of cut or operation performed on the workpiece. Different tools are used for tasks such as roughing, finishing, chamfering, or grooving. Proper tool selection is essential to ensure accurate machining and minimize errors in the final product. The setup phase also involves configuring the machine’s parameters to align with the programmed instructions, ensuring everything is calibrated for optimal performance.

Machining Process

The machining process begins once the CNC lathe is programmed and set up. This phase involves the actual turning of the material, where the programmed G-code instructions come to life. The lathe spins the material around a central spindle while the fixed cutting tool shapes the material according to the set parameters. Repetitive cycles, like the G71 and G72 roughing cycles, are used to minimize the amount of code that has to be written and provide more control over complex shapes and operations. These cycles follow the contour programmed between specific points and are crucial for material removal along different axes.

Quality Check

After the machining process, a rigorous quality check is necessary to ensure the part meets all specified standards. This includes dimensional checks using precise measuring tools to verify that the part aligns with design specifications. Surface finish and roughness are also evaluated, as these can significantly impact the part’s functionality. Non-Destructive Testing (NDT) techniques may be employed to detect any internal defects without damaging the part. Ensuring the machined part passes all these checks is crucial for maintaining high quality and functionality in the final product.

By adhering to these detailed steps, a CNC lathe machine efficiently transforms raw materials into precise, functional parts, showcasing the synergy of advanced technology and meticulous engineering.

Types of CNC Lathe Machines

CNC lathe machines are categorized based on the number of movement axes they incorporate, which significantly affects their functionality and the complexity of tasks they can perform. Here, we explore the different types of CNC lathes from the most basic to the most advanced.

2-Axis CNC Lathe

The 2-axis CNC lathe is the foundational model in CNC machining, equipped with X and Z axes. It excels in basic turning operations such as outer and inner diameter machining, facing, drilling, and tapping. The design simplicity of this lathe makes it a staple in many manufacturing settings, particularly suitable for straightforward cylindrical parts.

3-Axis CNC Lathe

Adding a C-axis to the basic 2-axis setup, the 3-axis CNC lathe introduces the capability for angular positioning, enabling operations like milling, drilling, and tapping. This type of lathe is more versatile, allowing for more complex operations including helical milling, which involves the synchronized rotation of the part. The addition of live tooling means that operations traditionally performed by milling machines can now be executed on a lathe, enhancing efficiency and reducing the need for multiple setups.

4-Axis CNC Lathe

A 4-axis CNC lathe includes a secondary tool carrier equipped with its own X and Z axes, often positioned opposite the first tool carrier. This setup not only speeds up material removal by allowing simultaneous turning but also supports complex machining tasks. The added axis typically is a Y-axis, enhancing the machine’s ability to perform off-center machining, crucial for more intricate and detailed shapes.

5-Axis CNC Lathe

The 5-axis CNC lathe introduces an additional Y-axis and sometimes a B-axis, expanding the lathe’s capability to handle complex milling operations with driven tooling. This machine setup is particularly beneficial for parts requiring multiple sides machining in a single setup, significantly reducing cycle times and improving precision.

6 or More Axis CNC Lathes

Machines with 6 or more axes represent the pinnacle of CNC lathe technology, incorporating multiple rotary axes that can operate around both the X, Y, and Z axes. These lathes are designed for highly sophisticated machining needs that require precise control over complex geometries and are typically used in advanced aerospace, automotive, and medical manufacturing. The additional axes facilitate the machining of intricate designs with high precision and minimal human intervention.

Each type of CNC lathe brings a unique set of capabilities to the table, catering to various manufacturing requirements from simple to complex parts. Understanding the operational capabilities of each type helps in selecting the right CNC lathe for specific manufacturing tasks, ensuring efficiency and precision in production.

Common Operations Performed on a CNC Lathe

Turning is the most common operation we perform on a CNC lathe. This process involves removing excess material from the outer diameter of a workpiece to achieve the desired diameter. There are two primary types of turning operations: rough and finish. Rough turning is focused on removing as much material as possible in the shortest time, often without regard for the surface finish or final dimensions. Finish turning, on the other hand, aims to achieve a smooth surface finish and precise dimensions.

Facing

Facing is another crucial operation in CNC lathe machining. It involves reducing the length of the workpiece to match specific requirements. The operation is performed by moving the cutting tool along the radius of the workpiece, which is held perpendicular to its axis of rotation. This ensures that the end of the workpiece is smooth and flat, matching the expected part length accurately.

Drilling

Drilling on a CNC lathe involves creating holes in the workpiece. The diameter of the hole corresponds to the size of the drill bit used. For optimal results, the drill bit must be correctly positioned, either in a lathe tool holder or a tailstock drill holder, as the workpiece rotates. This operation is essential for preparing the workpiece for further machining processes or for fitting parts together in assembly.

Boring

Boring is used to enlarge or refine the diameter of an existing hole in a workpiece. A single-point cutting tool is used, entering the workpiece axially to shape or deepen the hole. It’s important to note that boring cannot create new holes; it only enlarges or perfects pre-existing ones. This operation is particularly useful for achieving precise hole dimensions and for correcting holes that are not perfectly round.

Threading

Threading involves creating helical grooves along the outer surface of the workpiece. This operation uses a thread-shaped cutting tool bit that moves longitudinally along the workpiece while it rotates. Threading requires precise machine settings, especially if multiple passes are needed to achieve deeper threads. Proper setup ensures that each pass of the tool begins at the same location on the workpiece, maintaining the consistency and quality of the threads.

These operations highlight the versatility and precision of CNC lathes, making them indispensable in modern manufacturing for producing complex parts with high accuracy.

Industries Using CNC Lathe Machines

CNC lathe machines are pivotal in various industries due to their high precision, efficiency, and ability to handle complex machining tasks. Here’s how different sectors benefit from CNC lathe technology:

Aerospace

In the aerospace industry, CNC machining is crucial for producing and maintaining aircraft and space parts. Components such as airframes, jet engines, and landing gear are typically made from titanium alloy due to its strength-to-weight ratio and high-temperature resilience. Aerospace parts like engine components, airfoils, and antennae require extreme precision due to their complex designs and geometries. Precision CNC Milling and Turning are predominantly used to achieve the necessary accuracy, with parts such as screws, nuts, and connector pins being precisely crafted to meet rigorous standards.

Automotive

The automotive sector relies heavily on CNC machining for its unparalleled precision and efficiency, which are essential for vehicle safety and performance. CNC machines produce a wide array of automotive parts including engine components like pistons and cylinder heads, gearbox cases, and intricate car body parts such as dashboards and steering wheels. The ability to perform complex machining operations allows for the production of components that are both durable and intricate, enhancing vehicle performance and fuel efficiency.

Medical

Precision is critical in the medical field, where CNC machining is used to produce complex and highly detailed parts such as orthopedic implants, surgical tools, and components of imaging equipment. The technology’s capability to work with a variety of materials and maintain high precision makes it ideal for creating items that directly impact patient care, including MRI scanners and prosthetics.

Electronics

In electronics manufacturing, CNC machining is used to create high-precision parts like circuit boards, enclosures, and RF components. The technology’s precision is vital for ensuring the functionality and reliability of electronic devices. CNC machines are especially beneficial in producing the intricate designs and fine details required in consumer electronics, such as the metal alloy casings for smartphones and laptops.

Oil & Gas

The oil and gas industry demands robust and precise components capable of withstanding extreme conditions. CNC machining is extensively used to manufacture critical parts such as drilling tools, valves, and pipe fittings. The precision and strength of CNC-machined parts are essential for maintaining safety and efficiency in exploration and production activities.

These examples underscore the versatility and indispensability of CNC lathe machines across various industries, highlighting their role in modern manufacturing processes.

Benefits of Using CNC Lathe Machines

Increased Machining Accuracy

One of the standout advantages of CNC lathe machines is their ability to achieve high precision in machining. These machines can maintain tolerances as small as 0.004 mm, allowing for the creation of parts that meet exact specifications with minimal deviation. The precision of CNC machines is particularly beneficial in industries where even the slightest inaccuracies can lead to significant issues, such as aerospace and healthcare.

Complex Part Production

CNC lathe machines excel at producing complex shapes that would be challenging or impossible to duplicate with manual machining. The integration of sophisticated design software enables these machines to handle intricate designs with ease. This capability allows for the production of everything from simple parts to complex components necessary for various applications, enhancing the versatility of manufacturing processes.

Reduced Human Error

The autonomous operation of CNC machines significantly reduces the risk of human error. Since these machines operate based on precise computer instructions, the likelihood of mistakes due to manual intervention is minimized. This not only ensures the quality and consistency of the products but also enhances safety by reducing the direct interaction of operators with the machinery. Operators can oversee the process remotely, focusing on supervisory roles and maintenance to prevent breakdowns, which further contributes to a safer working environment.

Cost Efficiency

Adopting CNC technology can lead to substantial cost savings in several ways. Firstly, the initial setup costs, while significant, are offset by the high output rate and reduced production costs over time. CNC machines require fewer operators, which lowers labor costs. Additionally, the precision of CNC machining results in less material waste, further driving down costs. Energy consumption is also optimized, contributing to ongoing operational savings. These factors combined make CNC machining an economically attractive option for businesses looking to enhance their production efficiency without compromising quality.

Through this comprehensive exploration of CNC lathe machines, we have journeyed from their historical origins to their pivotal role in modern manufacturing, elucidating their operational mechanics, diverse types, and the myriads of operations they can perform. We’ve witnessed how this technology not only embodies the pinnacle of precision and efficiency in the production of complex components across various industries but also acts as a cornerstone for innovation in manufacturing processes. The benefits of employing CNC lathe machines, including increased machining accuracy, the capability for complex part production, significant reductions in human error, and overall cost efficiency, underscore their indispensable value to contemporary manufacturing landscapes.

As we look toward the future, the continued advancement and integration of CNC lathe technology promise to further revolutionize the manufacturing sector, driving forward economic progress and industrial innovation. With their ability to adapt to complex machining requirements and support the seamless execution of intricate designs, CNC lathes are not just tools but partners in the ever-evolving realm of manufacturing. Their enduring significance is a testament to the ingenuity of human invention and a reminder of the endless possibilities that precision engineering can unlock.

FAQs

What exactly is a CNC lathe machine?

A CNC lathe, also known as a CNC turning machine, is a type of machine that rotates a workpiece on a spindle while a fixed cutting tool shapes the material. Unlike traditional machines, a CNC lathe operates based on coded instructions programmed into a computer, which controls the movements of the components.

How does a CNC lathe differ from a conventional lathe?

The primary difference between a CNC lathe and a conventional lathe is the control mechanism. A CNC lathe is operated by Computerized Numerical Control (CNC), which means the machine’s movements are controlled automatically by a computer. In contrast, a conventional lathe requires manual adjustment and control by the operator for all movements.

What does “depth” refer to in a lathe machine?

In lathe machining, the “depth of cut” refers to the level to which the cutting tool penetrates into the workpiece. This depth, which impacts the tertiary cutting motion of the tool, is typically measured in thousandths of an inch or millimeters. The depth of cut generally ranges from 0.1 to 1.0 mm, depending on the specific operation.

What are the responsibilities of a CNC lathe machinist?

A CNC lathe machinist is responsible for creating designs for precision equipment and parts using blueprints or specialized computer software. They operate CNC machinery and manual tools to ensure that product dimensions adhere to specified requirements. Additional duties include inspecting materials for any defects and making necessary adjustments to maintain quality standards.

Leave a Comment