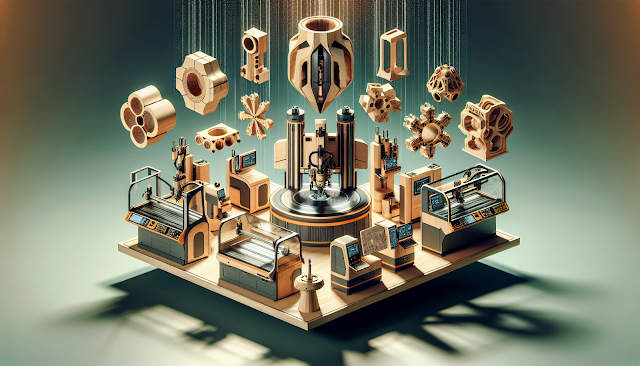

Exploring the world of CNC wood router unveils a sophisticated ensemble of computer-controlled machinery designed to intricately route out wood amongst other materials 1. These robots guide a router or spindle across three axes simultaneously, revolutionizing how we cut and shape wood 2.

As we dive into the merits of the best CNC wood router on the market, we’ll uncover the pivotal features that elevate these machines to essential tools for woodworking 2 5. Their ability to efficiently produce precise cuts on a regular basis makes them invaluable in both business and hobbyist settings 4.

Types of CNC Wood Router

Navigating through the diverse world of CNC wood router, we encounter a variety of models and configurations tailored to different needs and projects. Let’s break down the options:

- Model Variants:

- Types Based on Configuration:

- Horizontal Flat Table

- Point to Point Pod Systems

- Hybrid Flat Table plus Point to Point

- Vertical Routing Centers 7.

- Table Sizes and Brands:

Understanding these distinctions helps in selecting the right CNC wood router for your creative or business projects, ensuring efficiency and precision.

Key Features to Look for

When selecting a CNC wood router, several key features stand out as critical for ensuring efficiency, precision, and longevity in your woodworking projects.

- Essential Components and Specifications:

- Spindle and Motors: The heart of the CNC router, affecting cutting speed and quality. Look for a powerful spindle and reliable stepper motors 9.

- Cutting Area and Machine Base: Determines the size of projects you can undertake. A sturdy machine base contributes to stability and precision 9 10.

- Spindle Speed and Power: Influences the ability to cut through different materials. Higher spindle speeds allow for finer cuts 10.

- Accuracy and Repeatability: Essential for consistent production quality. Opt for routers with high accuracy and repeatability ratings 10.

- Operational Efficiency and Quality:

- Vacuum System: A good vacuum system is crucial for clean operation and material hold-down 11.

- Dust Collection: Efficient dust collection systems keep the workspace clean and maintain air quality 4.

- Software Integration: The ability to use various control software and design programs for precise cutting 6.

- Safety Features: Look for routers equipped with emergency stops, interlock switches, and enclosures for operator safety 7.

- Additional Considerations for Business:

- Labor and Cost Efficiency: CNC routers offer immediate labor savings and can lead to additional business through increased efficiency and product quality 12.

- Financing Options: Affordable financing can make acquiring a high-quality CNC router more accessible 12.

- Manufacturer Support: Consider the availability of parts, technical support, and the manufacturer’s reputation for long-term reliability 12.

By focusing on these key features and considerations, you can select a CNC wood router that meets your project requirements and enhances your woodworking capabilities.

Top Uses of CNC Wood Router

CNC wood router, with their remarkable versatility, have become indispensable in various industries, transforming raw materials into intricate designs and functional products. The applications of these machines are vast, ranging from creating fine art to building robust architectural elements. Here, we delve into some of the primary uses:

- Furniture and Interior Design: From crafting bespoke modern furniture like beds and dining sets to intricate staircases and custom cabinets, CNC routers bring imagination to life in the furniture industry 13. They are pivotal in customizing kitchens with crafted cabinets, side panels, and unique drawer fronts 13.

- Sign Making and Advertising: CNC routers excel in sign making, offering V-bit carving, 3D carving, and intricate engraving. Their ability to produce clean, precise cuts through various materials makes them ideal for creating advertising signs and displays with unique textures and styles 13 14.

- Architectural and Decorative Applications: Utilizing CNC routers for architectural millwork allows for the creation of exquisite details and delicate designs, adding unique touches to buildings and houses. They are also used in making prototypes, models, and parts for various industries, showcasing their efficiency and cost-effectiveness 15 16.

This broad spectrum of applications underscores the CNC wood router ‘s role as a transformative tool in manufacturing, design, and artistry, enabling creators to push the boundaries of what’s possible with wood and other materials.

Choosing the Right CNC Wood Router for Your Projects

Choosing the right CNC wood router for your projects involves a thoughtful consideration of several factors to ensure that your investment meets your creative and operational needs. Here’s a concise guide to navigate through the selection process:

- Assess Your Projects and Materials:

- Project Size and Complexity: Consider the scale of your projects and the materials you plan to work with. Larger, more complex projects may require a router with a larger table and higher spindle power 18 20.

- Material Compatibility: Different CNC routers are optimized for various materials. Ensure the router you choose is well-suited for wood, metal, or plastic, depending on your needs 20.

- Budget and Features:

- Budget Range: CNC wood router are available from $2,580 to $38,000. Establish a budget early in your search to narrow down options 6.

- Key Features to Look For:

- Software Compatibility: Ensure the router supports user-friendly software and check if it requires proprietary software 10 11.

- Motor System and Spindle Power: Higher spindle power is better for denser materials and larger bits 20.

- Accuracy and Speed: Required accuracy and speed for your projects. High accuracy ratings ensure clean and precise cuts 21.

- Manufacturer and Support:

- Customer Support: Opt for brands that offer robust customer service, including technical assistance and access to spare parts 10 20.

- User Reviews and Testimonials: Reading user experiences can provide valuable insights into the reliability and performance of the router models 10.

- After-Sale Service: Consider the quality of after-sale service, as it’s crucial for troubleshooting and maintenance 11.

By methodically evaluating these aspects, you can ensure that the CNC wood router you select not only fits within your budget but also supports the breadth of your creative endeavors, offering the flexibility, precision, and reliability needed for your woodworking projects.

Conclusion

Through meticulous exploration and evaluation, this article has offered a comprehensive guide on the best CNC wood router available, shedding light on their unparalleled ability to transform and enhance woodworking projects. By delving into the varieties, essential features, and practical applications of these innovative machines, readers are equipped with the knowledge to select a CNC wood router that aligns with their project requirements, ensuring efficiency, precision, and creativity. Emphasized throughout has been the importance of compatibility with project scale, material types, and operational needs, underscoring the need for a thoughtful selection process.

In navigating the future of woodworking and creative projects, the insights provided serve as a foundational resource for artisans, hobbyists, and businesses alike. By highlighting the significance of CNC wood router in pushing the boundaries of design and manufacturing, the article underscores their role as catalysts for innovation and excellence. Readers are encouraged to leverage this knowledge in making informed decisions that foster enhanced craftsmanship, productivity, and artistic expression, thereby unlocking new realms of possibility in woodworking and beyond.

FAQs

What CNC Router Should Hobbyists Consider?

For hobbyists looking to delve into CNC routing, the 2021 update highlights the top 12 CNC routers ideal for small businesses and hobbyist projects. This list includes notable models such as the Pocket NC, Maslow CNC, Carbid 3D Nomad 883 Pro, and the 3018 GRBL control DIY mini CNC. Other recommended options are the MYSWEETY DIY CNC Router Kit 1610 GRBL control, Axiom Precision Axiom Pro V5, Ooznest Workbee, and SainSmart’s Genmitsu CNC 3018-PRO, catering to various needs and expertise levels in CNC routing.

Is It Possible to Generate Income with a CNC Wood Machine?

Yes, utilizing a CNC wood machine can be a lucrative venture. Apart from producing finished items, one can also offer specialized woodworking services and conduct workshops. This approach caters to individuals eager to learn woodworking skills or those seeking assistance with their DIY projects, thereby opening multiple revenue streams.

Which CNC Router Is Best for Beginners?

The ShopSabre 23 stands out as the premier DIY CNC router for beginners, thanks to its straightforward assembly and setup process. Designed to be user-friendly for novices, it ensures accurate and precise cutting for a variety of woodworking projects, making it an economical choice without compromising on quality.

What Type of Wood Is Ideal for CNC Routing?

Birchwood is highly recommended for CNC routing due to its light color, wavy grain patterns, and durability, comparable to oak or walnut. Its resistance to chipping and denting, coupled with its excellent ability to hold screws, makes it a preferred choice for constructing furniture or any structural components requiring a robust and reliable wood type.

References

[1] – https://www.elephant-cnc.com/blog/the-most-complete-cnc-router-machine-guide/ [2] – http://benchmark.20m.com/tools/CNC_Router/CNC_RouterBasics/CNC_RouterBasics.html [3] – https://www.youtube.com/watch?v=NWDrWbCbI3s [4] – https://www.treatstock.com/guide/article/129-what-is-cnc-routing [5] – https://www.xometry.com/resources/machining/what-is-a-cnc-router/ [6] – https://www.stylecnc.com/cnc-wood-router/ [7] – https://www.cnc.works/features-to-look-for-when-buying-a-wood-router-machine [8] – https://www.globalspec.com/learnmore/manufacturing_process_equipment/machine_tools/cnc_routers [9] – https://www.youtube.com/watch?v=2L-JUhO-Y0M [10] – https://www.bobscnc.com/blogs/news/hoow-to-select-the-best-cnc-router-for-your-shop [11] – https://woodweb.com/knowledge_base/Advice_on_Choosing_a_CNC_Router.html [12] – https://www.woodworkingnetwork.com/best-practices-guide/panel-processing/five-key-factors-choosing-right-cnc-router [13] – https://www.cncsparetools.com/new/Six-Popular-Applications-for-CNC-Router-Machine.html [14] – https://www.camaster.com/10-applications-for-your-cnc-router-machine/ [15] – https://www.omni-cnc.com/cnc-wood-router-finding-its-use-in-a-range-of-amazing-applications/ [16] – https://forsuncnc.com/cnc-router-applications/ [17] – https://www.youtube.com/watch?v=ktARgAkZFrw [18] – https://www.popularwoodworking.com/review/cnc-router/ [19] – https://www.youtube.com/watch?v=CKFUyZSiIaM [20] – https://www.elitemetaltools.com/article/what-are-top-10-things-consider-when-purchasing-cnc-router [21] – https://www.biesse.com/na/wood/magazine/corporate/five-key-factors-in-choosing-the-right-cnc-router [22] – https://goldstarcnc.us/cnc-machines-information/introduction-to-cnc-router-in-woodworking/

Leave a Comment