Selecting the perfect wood CNC machine for your workshop marks a pivotal decision in the enhancement of your woodworking capabilities. The advent of CNC (Computer Numerical Control) technology has revolutionized how we approach woodwork, allowing for precision, efficiency, and creativity that was once deemed unattainable. Whether you’re a hobbyist aiming to elevate your projects or a professional seeking to streamline your production, understanding the integral role of a wood CNC machine in your work space is fundamental. Its significance stretches beyond mere equipment; it’s an investment in the quality and scope of what you can achieve.

In our exploration, we will delve into the evolution of wood CNC machines, elucidating how advancements in technology have made these tools more accessible and adaptable to various needs. We’ll discuss key features to consider when choosing the right wood CNC machine, balancing considerations of size, power, and functionality to match your specific projects. Additionally, we’ll highlight top brands and models, offering insights that could guide your decision. Lastly, we will look at creative projects and applications for wood CNC machines, showcasing the broad potential these machines hold for transforming ideas into tangible creations. Our journey through these facets will equip you with the knowledge needed to make an informed selection, ensuring your workshop is enhanced by the right tool for your woodworking aspirations.

Exploring the Evolution of Wood CNC Machine

The Journey from Handcrafting to Precision Automation

The evolution of wood CNC machine began with the pioneering work of John T. Parsons in the late 1940s, who developed the first numerical control systems as part of an Air Force research project 78. This innovation marked the transition from manual handcrafting to automated precision, fundamentally changing woodworking and manufacturing practices 9.

Significant Milestones in Wood CNC Development

By the 1950s, the introduction of the Cincinnati Hydro-Tel milling machine, developed in collaboration with MIT, showcased the commercial viability of CNC technology 7. The shift from punched tape to digital technologies through the 1960s and 1970s further enhanced the capabilities and efficiency of CNC machines, culminating in the widespread adoption of CNC technology in the 1980s and 1990s 8.

Impact on the Woodworking Industry

The integration of CNC machines has revolutionized the woodworking industry by enabling the creation of complex and precise wood products with unprecedented speed and accuracy 14. This technological advancement has not only improved production efficiency but also expanded the creative possibilities within the industry, allowing for intricate designs and consistent quality in woodworking projects 14.

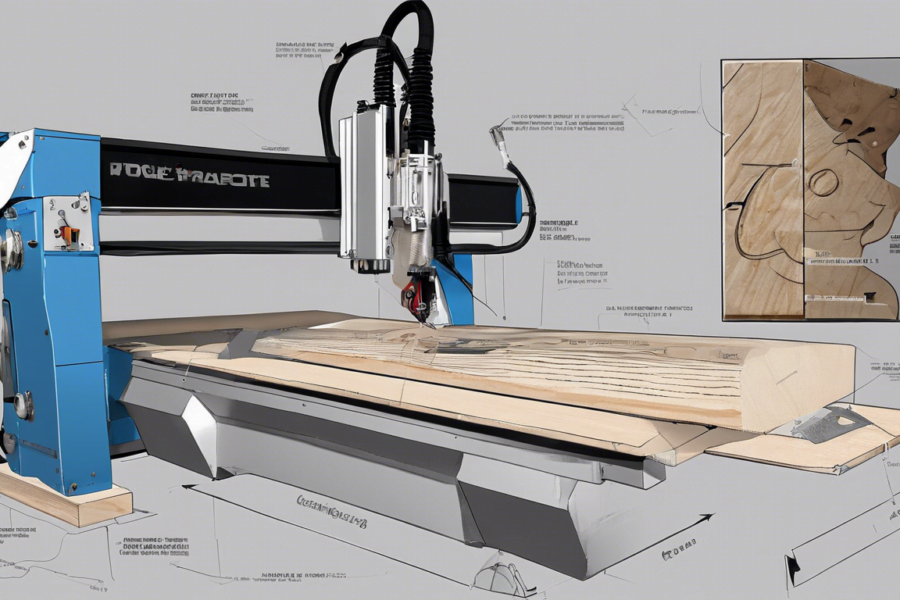

Key Features to Consider When Choosing a Wood CNC Machine

Size and Work Area

When selecting a wood CNC machine, the size of the work area is crucial. Larger tables not only offer versatility but also material savings, making a moderate increase in investment worthwhile. For instance, a 5 x 10 machine often provides better yield when nesting compared to a 4 x 8 machine, due to more efficient use of materials 21.

Spindle Quality and Power

The spindle is the heart of the CNC machine, dictating performance and the quality of outputs. High-quality spindles ensure precision and efficiency, crucial for detailed woodworking. It’s important to select a spindle that matches the speed and power requirements of your projects to avoid inefficiencies and potential damage 23.

Software Compatibility and Ease of Use

Choosing the right software is essential for maximizing the potential of your wood CNC machine. Software compatibility affects everything from design possibilities to the execution of precise cuts. Look for systems that integrate CAD and CAM capabilities and offer user-friendly interfaces to streamline your workflow 2527.

Safety Features and Durability

Safety cannot be overlooked when operating high-power machinery like CNC machines. Modern CNC machines come equipped with advanced safety features that prevent accidents and ensure a safe working environment. Always ensure that these features are compliant with regulatory standards and that the machine is built to withstand the rigors of woodworking 29.

Top Wood CNC Machine Brands and Models

In exploring top wood CNC machine brands and models, it’s crucial to consider user experiences and reviews, which highlight the practicality and efficiency of these machines. Shapeoko emerges as a standout brand, particularly for beginners. Its machines are celebrated for their ease of use and comprehensive features, such as the Shapeoko 4, which offers a great balance of price and capabilities 35. Additionally, Axiom’s Iconic-4 is noted for its robust features at a smaller scale, making it suitable for varied woodworking projects 36.

On the other hand, the Next Wave Shark HD500 is appreciated for its innovative software that enhances 3D surface mapping, allowing for precise and creative woodworking 36. These models exemplify the diverse offerings in the market, catering to different needs from beginners to advanced users, thus ensuring that every woodworker finds a machine that aligns with their project requirements and skill level 3236.

Creative Projects and Applications for Wood CNC Machines

From Furniture to Art: The Versatility of CNC Machines

CNC machines have revolutionized woodworking, enabling the creation of everything from intricate furniture to unique works of art 48. The precision of these tools allows for complex designs that are nearly impossible with traditional methods 48.

Innovative Use Cases and Inspirational Ideas

Woodworkers use CNC machines for a variety of projects, such as custom cabinetry, decorative elements, and even sculptural pieces 48. The ability to cut, carve, and shape wood precisely opens up endless possibilities for creative expression 48.

Tips for Beginners Starting with Wood CNC Projects

For those new to wood CNC projects, numerous resources are available online, including tutorials and forums 48. These platforms offer guidance on selecting the right machine, using software effectively, and mastering techniques to bring creative ideas to life 48.

Conclusion

Through the course of this article, we’ve traversed the significant terrain of selecting the perfect wood CNC machine for your workshop, delving deep into the evolution of these machines, their key features, top brands, and the boundless creative applications they offer. This exploration not only sheds light on the technological advancements that have shaped the woodworking industry but also provides a comprehensive guide to making an informed investment in a tool that will significantly enhance your craft. By considering factors such as size, spindle quality, software compatibility, and safety features, alongside evaluating the brands and models through the lens of user experiences, we’ve aimed to equip you with the knowledge needed to pick a machine that suits your projects’ scope and scale perfectly.

The broader implications of integrating a wood CNC machine into your woodworking practice stretch far beyond its immediate operational capabilities. It opens up a realm of creative possibilities, empowering you to bring intricate designs and ideas to life with precision and efficiency that manual techniques cannot match. The selection process, grounded in understanding the machine’s features and potential applications, is pivotal to unlocking these possibilities. As we conclude, remember the importance of choosing a wood CNC machine that not just meets but exceeds your expectations, setting the stage for innovation and creative exploration in your woodworking endeavors. Whether you’re a seasoned professional or a passionate hobbyist, the journey towards mastering wood CNC technology begins with the first step of selection, promising a future rich with creative potential and unparalleled workmanship.

FAQs

1. What factors should be considered when selecting a CNC machine?

To choose the best CNC machine, it’s essential to evaluate several critical aspects:

- Define your objectives and goals for using the machine.

- Consider the type and configuration of the machine.

- Assess the size and capacity needed for your projects.

- Check the available tooling and accessories.

- Review the control system and software.

- Understand the maintenance and support services.

- Plan your budget and consider the potential return on investment.

2. Which CNC machine is recommended for beginners working with wood?

For those new to CNC machining, the SYIL brand is highly recommended. SYIL provides an array of wood CNC machines and CNC router tables that are particularly tailored for beginners. These machines feature user-friendly interfaces and intuitive controls, making the learning process both simple and enjoyable.

3. What are the best CNC machines for woodworking beginners?

Beginners in woodworking should look for CNC machines that are straightforward and easy to operate. The Shapeoko CNC and the Onefinity CNC are excellent choices due to their affordability and ease of use. Additionally, the Carbide 3D Nomad and the BobsCNC E4 are also popular among beginners for their user-friendly features.

4. Which types of wood are ideal for CNC machining projects?

Ash, Cherry, Walnut, and Maple are the best types of wood for CNC projects. These hardwoods are preferred due to their superior mechanical properties, such as hardness and toughness, making them suitable for items like hockey sticks, tables, and stools.

References

[1] – https://community.carbide3d.com/t/best-option-for-a-total-beginner/66616

[2] – https://www.youtube.com/watch?v=2L-JUhO-Y0M

[3] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[4] – https://www.woodmagazine.com/tool-reviews/a-buyers-guide-to-benchtop-cnc-machines

[5] – https://insidethekerf.com/blog/what-is-a-cnc-woodworking-machine/

[6] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[7] – https://laszeray.com/the-history-of-cnc-machinery/

[8] – https://capablemachining.com/blog/the-history-of-cnc-machines/

[9] – https://www.james-engineering.com/history-of-cnc

[10] – https://frontrangecnc.com/2023/04/15/the-evolution-of-industrial-cnc-routers-a-look-at-the-past-present-and-future/

[11] – https://wooddesigner.org/technological-developments-woodwork-trades/

[13] – https://www.tensilemillcnc.com/blog/the-impact-of-cnc-machines-on-industrial-automation-a-deep-dive

[14] – https://medium.com/@thewoodworkgallery/unleashing-the-power-of-cnc-machines-for-woodworking-4e904185c51b

[15] – https://www.acctekgroup.com/industry-news/The-CNC-router-changed-the-woodworking-industry.html

[16] – https://www.shopsabre.com/mastering-cnc-machines-for-woodworkers/

[17] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[18] – https://www.youtube.com/watch?v=uxJ455Lz58k

[19] – https://www.reddit.com/r/CNC/comments/13qwt40/im_planning_to_make_my_own_cnc_how_do_i_decide/

[20] – https://uk.xtool.com/blogs/buyer-guide/wood-cnc-machine

[21] – https://woodweb.com/knowledge_base/What_Size_CNC_Table_Should_I_Have.html

[22] – https://www.superiorspindle.com/spindle-maintenance-guide-how-to-test-cnc-spindle-performance/

[23] – https://www.syil.com/blog/ultimate-guide-spindle-cnc-how-works

[24] – https://gowico.com/blogs/technical-insights/choosing-cnc-spindles-what-you-need-to-know

[25] – https://forsuncnc.com/what-software-to-use-for-a-cnc-router/

[26] – https://www.reddit.com/r/hobbycnc/comments/jxrtac/what_software_to_use_for_a_desktop_cnc/

[27] – https://forum.onefinitycnc.com/t/software-recommendations/8450

[28] – https://www.mmsonline.com/articles/five-safety-considerations-for-cnc-machinists

[29] – https://kaast-usa.com/cnc-machine-safety-guidelines

[30] – https://www.uti.edu/blog/cnc/machining-safety

[31] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[32] – https://forestry.com/wp/best/best-cnc-machines-for-woodworking/

[33] – https://www.stylecnc.com/blog/top-10-best-cnc-machine-manufacturers-brands.html

[34] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[35] – https://www.youtube.com/watch?v=ktARgAkZFrw

[36] – https://www.woodmagazine.com/tool-reviews/a-buyers-guide-to-benchtop-cnc-machines

[37] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[38] – https://www.quora.com/What-has-your-experience-been-using-CNC-for-wood-working-projects

[39] – https://forum.onefinitycnc.com/t/got-sucked-into-the-hype-damn-reality-check-for-everyone/21026

[40] – https://www.youtube.com/watch?v=wLkqMhrQsZw

[41] – https://www.pinterest.com/dantwin2/cnc-projects/

[42] – https://www.youtube.com/watch?v=r8l6Uzo9Pv0

[43] – https://www.pinterest.com/dantwin2/cnc-projects/

[44] – https://www.youtube.com/watch?v=wLkqMhrQsZw

[45] – https://www.cncmasters.com/cnc-router-woodworking-projects/

[46] – https://www.youtube.com/watch?v=fRWQ2kYjOds

[47] – https://www.youtube.com/watch?v=9rQVKJgksT4

[48] – https://www.youtube.com/playlist?list=PL1FwpwIc0fyqCc5W56EwzpRrh0-ND_z0h

[49] – https://www.reddit.com/r/hobbycnc/comments/wehpyd/cnc_recommendations_for_woodshop/

[50] – https://woodweb.com/knowledge_base/Advice_on_Choosing_a_CNC_Router.html

[51] – https://www.finewoodworking.com/forum/cnc-machines-what-do-you-think

[52] – https://www.midlandscnc.co.uk/2022/05/the-best-types-of-wood-for-cnc-machining/

[53] – https://www.biesse.com/in/wood/magazine/blog/guide-to-choose-cnc-machines

[54] – https://www.scan2cad.com/blog/cnc/choose-cnc-machine/

Leave a Comment