In the evolving world of manufacturing and production, CNC programming has emerged as a cornerstone of modern fabrication processes. This intricate method of controlling machine tools with the aid of computers revolutionizes the way components are manufactured, ensuring precision, efficiency, and repeatability. As we delve into this topic, it’s essential to understand not just the mechanics of CNC programming but its significance in pushing the boundaries of what’s possible in manufacturing today. With its critical role in everything from prototyping to full-scale production, mastering CNC programming is more than a technical skill—it’s a gateway to innovation in numerous industries.

Our exploration will take us through the fundamentals of CNC programming, from breaking down what it entails to understanding how it works. We’ll cover the different types of CNC programming, the most important codes you’ll need to know, and how to create these codes effectively. Additionally, we’ll look at the best CNC programming software available, its applications across various industries, and provide practical tips for successful CNC machine programming. By offering a comprehensive overview, we aim to equip you with everything you need to know to navigate the complexities of CNC programming and leverage its capabilities to the fullest.

What is CNC Programming?

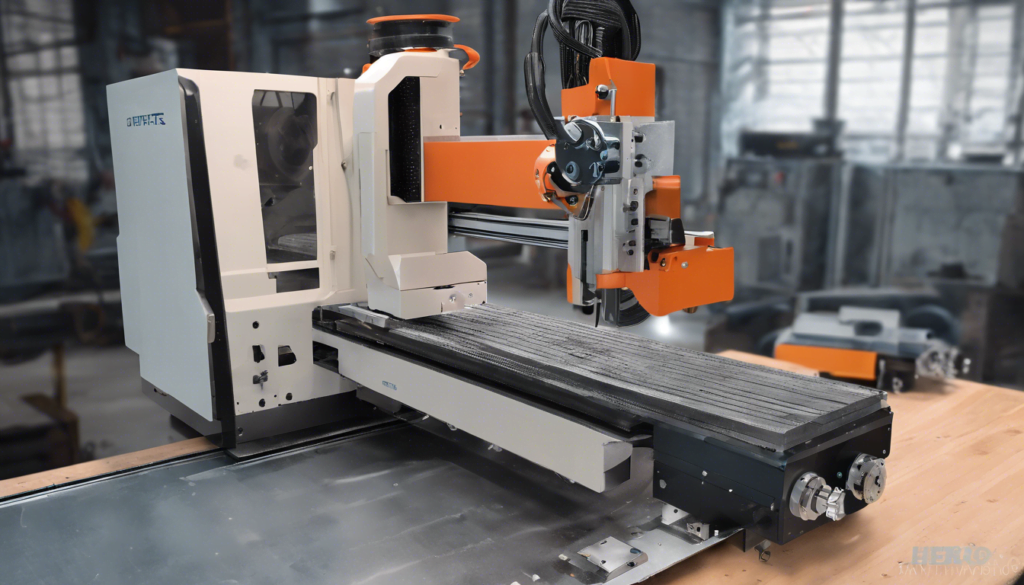

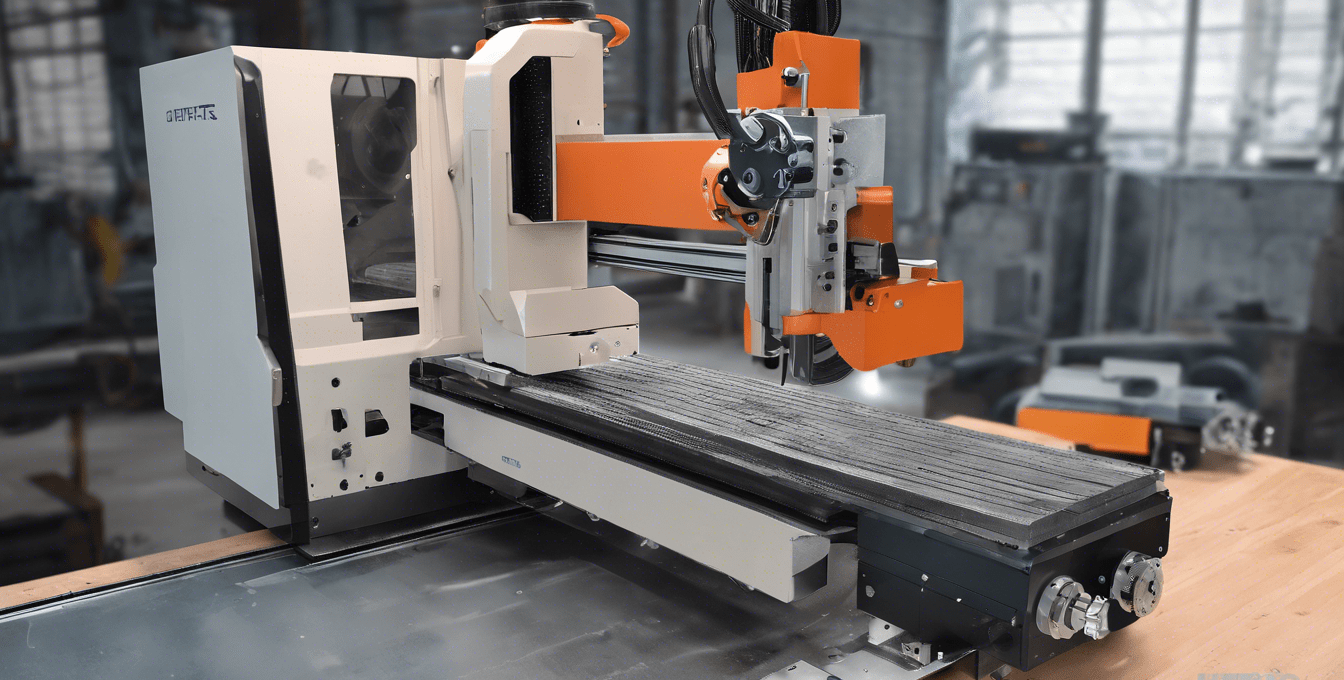

CNC programming, or computer numerical control programming, is the craft of creating coded instructions that guide CNC machines in manufacturing parts with high precision. These machines, integral to modern manufacturing, execute complex operations like cutting, milling, and drilling on various materials. The process begins with the development of a program, typically written in G-code, which directs the machine’s movements, spindle speeds, feed rates, and other operational parameters.

The essence of CNC programming lies in its ability to transform a 3D CAD (computer-aided design) model into a set of machine-readable instructions. These instructions are crucial for the CNC machine as they dictate every action from the positioning of the tool to the execution of the cut, ensuring the final product matches the original design with exactitude.

Moreover, CNC programming is not just about inputting data into machines; it involves selecting the right tools and parameters to optimize the manufacturing process. This selection process includes determining the appropriate cutting tools, feed rates, and the sequence of operations. This meticulous planning is essential for enhancing the efficiency and quality of production.

The use of specialized software is a cornerstone of effective CNC programming. These programs provide a graphical interface that helps in creating, editing, and managing CNC codes. With advancements in software technology, these tools have become more user-friendly and powerful, offering features that simplify the complexities of CNC programming. The choice of software often depends on the specific needs of the operation and the type of CNC machine being used, making it crucial to select a solution that aligns with the organizational requirements.

CNC programming significantly elevates the level of automation in manufacturing. By enabling the production of complex parts with consistency and speed, it plays a pivotal role in enhancing productivity and flexibility in manufacturing operations. This automation not only helps in achieving high-quality outputs but also in maintaining them over large production volumes, making CNC programming a fundamental skill in the field of modern manufacturing.

How Does CNC Programming Work?

CNC programming transforms a design into precise operational commands for CNC machines, ensuring the accurate production of parts. The process starts with a design, typically in a 3D CAD format, which is then translated into machine-readable instructions through several meticulous steps.

Steps in CNC Programming

- Access the CAD Model: The first step involves accessing the 3D or CAD model of the product or part. This model serves as the blueprint for the CNC machining process.

- Convert CAD to CAM: Using CAM software, the CAD model is converted into a series of tool paths. These paths are designed based on the part’s features such as holes, slots, and contours.

- Generate Machining Code (G-code): After the tool paths are established, the CAM software generates the machining code, commonly known as G-code. This code will guide the CNC machine’s actions during the manufacturing process.

- Feed G-code into CNC Machine: The programmer uploads the G-code into the CNC machine. With everything set, the cycle start button is pressed, initiating the production of the part.

- Verify Tool Paths: It’s crucial to verify the tool paths to ensure there are no risks of the machine colliding with the workpiece or fixtures. Verification can be done manually or using software that simulates the tool paths.

- Execute the Code: The machine follows the G-code instructions to cut the material. This includes movements, speed adjustments, and tool changes as dictated by the code.

- Post-Processing: After the machining process, post-processing steps like deburring and polishing might be necessary to finish the part.

This systematic approach to CNC programming allows for the efficient and precise production of complex parts, essential in modern manufacturing.

Types of CNC Programming

Manual CNC Programming

Manual CNC programming, often considered the most traditional form, requires the programmer to input commands directly into the CNC machine using the same language the machine executes. This method is particularly effective when dealing with simple jobs, high-volume work, or when the utmost efficiency of program execution is critical. We find it invaluable in scenarios where each second of production time impacts the competitive edge. Despite its advantages in optimizing cycle times and tool paths, manual programming demands a deep understanding of machine commands and is prone to human errors, making it less suitable for complex parts without extensive checks.

Conversational CNC Programming

Conversational programming simplifies the CNC programming process by allowing operators to input instructions directly at the machine using a more intuitive, plain language interface. This method is ideal for small lot sizes or when quick setup changes are necessary. It significantly reduces setup, programming, and execution times by using built-in data prompts to guide the operator through part geometry, material specifications, and tooling requirements. However, its simplicity also limits its use to simpler part geometries, as it lacks the flexibility to handle more complex tool paths.

CAM Programming

Computer-Aided Manufacturing (CAM) programming represents a more advanced approach, leveraging software to convert CAD designs into machine-readable instructions. CAM programming is particularly beneficial for handling complex parts and diverse machine types, as it automates much of the programming process. This method not only minimizes the need for detailed manual calculations but also enhances the accuracy and speed of program creation. The visual interface of CAM software helps in preemptively identifying potential issues in tool paths, thereby reducing the risk of errors. While CAM systems require an initial investment, they are increasingly considered essential in modern CNC operations for their efficiency and capability enhancements.

Most Important CNC Codes

G-Codes

G-code is the fundamental language used to control CNC machines. It consists of instructions that direct the movement of the cutting tool, with each line of code representing a single operation. This simplicity makes G-code easy to learn and use, even for those without extensive programming experience. G-codes are crucial for the automation of CNC machining, as they provide precise commands that the machine’s microcontroller can interpret and execute.

Some of the most commonly used G-codes include:

- G00: Rapid Positioning – Moves the tool quickly to the specified coordinates without cutting.

- G01: Linear Interpolation – Directs the tool to move in a straight line at a specified feed rate.

- G02: Circular Interpolation Clockwise – Guides the tool in a clockwise circular path.

- G03: Circular Interpolation Counterclockwise – Moves the tool in a counterclockwise circular path.

These commands are essential for performing basic and complex machining tasks, allowing for precise control over the machine’s movements.

M-Codes

M-codes, or Machine codes, control various functions of a CNC machine that are not directly related to the tool’s movement. These include actions like starting and stopping the machine, changing tools, and managing coolant flow. M-codes are specific to the machine’s controller and can vary between different CNC models and manufacturers.

Commonly used M-codes include:

- M00: Program Stop – Halts the machine for adjustments or troubleshooting.

- M02: End of Program – Marks the completion of the CNC program.

- M03: Spindle Start Clockwise – Activates the spindle in a clockwise direction.

- M06: Tool Change – Automates the process of changing tools during operation.

Understanding and using these M-codes effectively is vital for optimizing CNC machine operations and ensuring smooth and efficient production processes.

Other Important Codes

In addition to G-codes and M-codes, CNC programming includes several other codes that enhance machine functionality and programming flexibility. These include:

- G20/G21: Units Selection – Allows the programmer to set the measurement units (inches or millimeters) used in the program.

- G28: Return Home – Directs the tool to return to its home position, ensuring it starts from a known location for each new operation.

- G90/G91: Positioning Commands – Determines whether the machine interprets coordinates in absolute or relative terms, crucial for precise tool placement.

Each of these codes plays a specific role in the comprehensive control of CNC machines, contributing to the accuracy, efficiency, and safety of the machining process. Understanding how to use these codes effectively can greatly enhance the capabilities of CNC programming and the quality of the final products.

Creating CNC Programming Code

Creating CNC code is a critical step in the manufacturing process, allowing for the precise control of CNC machines to produce high-quality parts. This section will guide you through the steps involved in generating and exporting a 3D model, creating and confirming tool paths, and finally downloading the code to a CNC machine.

Generate and Export 3D Model

Firstly, we need to generate a 3D model that will serve as the basis for our machining operations. In applications like Fusion 360, the model is typically developed from a CAD file. Once the model is ready, it’s crucial to ensure it’s correctly aligned, especially if the pattern is imported from another software. For instance, when creating a projected toolpath, the pattern doesn’t need to be directly on the surface of the model but can ‘float’ directly above or below it.

Create Tool Paths

After the 3D model is set, the next step is to create tool paths. This involves using CAM software to convert the CAD model into machine-readable instructions. In Fusion 360, you can create various types of tool paths, such as profile (contour) tool paths and pocketing tool paths. Each tool path needs to be configured based on the bits you are using, the machine, and the material to ensure optimal results. For example, you might start with a pocket operation in Fusion 360, setting all necessary heights and passes, including multiple depths for hobbyist grade machines to enhance the cutting process.

Confirm Tool Paths

Once the tool paths are created, it is essential to confirm them to avoid any potential errors during the machining process. This can be done manually or using software simulations that show what the machine will do with the tool path before actual production. Fusion 360 offers a simulation feature that allows you to visualize and adjust the tool paths as needed. Ensuring the accuracy of these paths is crucial for the quality of the final product.

Download the Code to CNC Machine

The final step in creating CNC code is to download it to the CNC machine. This typically involves exporting the finalized code, usually in G-code format, from the CAM software to a device like a USB drive. Then, you transfer this code to the CNC machine. Before starting the machine, it’s important to ensure that the code is loaded correctly and that the machine is set up properly to execute the cutting operations as planned.

By meticulously following these steps, you can effectively create and implement CNC code, leading to precise and efficient manufacturing outcomes.

Best CNC Programming Software

Exploring the best CNC programming software involves understanding the capabilities, costs, and user experiences associated with each option. Here, we delve into some popular choices like Solidworks, Meshcam, Fusion 360, Vectric, and Mastercam, highlighting their strengths and potential limitations based on real user experiences.

Solidworks

Solidworks® is renowned for its comprehensive 3D modeling and 2D drafting capabilities, along with additional features like finite element analysis and mechanism simulation. For CNC machining, Solidworks® models can be seamlessly exported to any CAM package, supporting model-based definition. While it offers a robust platform for engineering and design, the software can be quite expensive for professional use, although a new $99/year subscription for hobbyists and makers makes it more accessible.

Meshcam

Meshcam stands out for its simplicity and effectiveness in handling STL files, making it a preferred choice for those new to CNC programming or working on less complex projects. Despite its ease of use, limitations may arise when dealing with more advanced requirements like milling with undercut bits or single-point threading. The software is available under a perpetual license ranging from $250-$500, which could be a consideration for those cautious about ongoing costs.

Fusion 360

Fusion 360® offers a powerful suite of tools covering the entire development cycle from design through to CAM. Its integration of CAD and CAM is seamless, and the software includes advanced simulation options to test parts before production. While Fusion 360® is highly regarded for its capabilities and a strong online community, some advanced CAM features are only available at an additional cost. The subscription model is affordable at around $300 per year, providing a cost-effective solution for many users.

Vectric

Vectric software is a leader in the hobby router market, praised for its user-friendly interface and effective CAM features, particularly for engraving. Although it lacks 3D CAD capabilities, it excels in 2D design and is highly regarded among those using CNC for milling and engraving. The software, however, is quite pricey, with costs around 660€ excluding VAT.

Mastercam

Mastercam is a mid-level CAM package known for its extensive feature set including multi-axis milling and turning. It offers a flexible pricing structure and the option for users to forgo annual maintenance fees, which adds to its appeal. Mastercam’s integration with SolidWorks is a bonus for those already familiar with that platform. Despite its steep learning curve, Mastercam remains a popular choice for its powerful machining capabilities.

Each of these software options has its own strengths and areas of specialization, making it important to choose based on specific needs and budget considerations. Whether you require simple, user-friendly software or a more robust system capable of handling complex machining tasks, there is a CNC programming software suited to every type of user.

Industries Applications for CNC Programming

CNC programming has revolutionized various industries by enhancing precision, efficiency, and customization capabilities. This section explores its impactful applications across healthcare, consumer electronics, aerospace, and automotive sectors.

Health Care

In the healthcare industry, CNC programming plays a pivotal role in manufacturing high-precision and custom medical devices. It is instrumental in producing essential components such as surgical instruments, orthopedic implants, and diagnostic equipment. For instance, CNC machines create intricate surgical tools like scalpels and forceps, which require exact specifications for successful surgeries. Similarly, the production of orthopedic implants like hip and knee replacements relies on CNC for achieving the complex geometries and tight tolerances essential for patient compatibility and functionality. Moreover, CNC technology supports rapid prototyping, accelerating the development and testing of new medical devices to ensure they meet the rigorous standards of the medical field.

Consumer Electronics

The consumer electronics sector benefits significantly from the precision and versatility of CNC machining. High-profile products like the Apple MacBook are crafted using CNC milling, which allows for the creation of durable aluminum bodies with intricate details such as keyboard holes and aesthetic contours. Additionally, CNC machining is crucial in the production of semiconductor components, which are foundational to electronic devices. The ability to machine precise parts like wafer carriers and heat sinks ensures the functionality and reliability of consumer electronics, ranging from smartphones to laptops.

Aerospace and Aircraft

Aerospace manufacturing demands the highest levels of precision and reliability, areas where CNC programming excels. The production of critical aircraft components, such as turbine blades, fuselage parts, and jet engines, relies heavily on CNC technology. For example, components made from titanium alloys, favored for their strength and heat resistance, are typically machined using CNC to meet exacting industry standards. CNC programming also supports the rapid prototyping of new designs, enhancing innovation and efficiency in aerospace development projects.

Automotive

In the automotive industry, CNC programming enables the production of both standard and customized components with high precision. This capability is crucial for developing new vehicle models and producing parts for high-performance vehicles that meet specific design and functional requirements. CNC machining not only ensures the quality and fit of automotive components but also integrates seamlessly into automated production lines, which improves manufacturing efficiency and reduces the likelihood of errors.

By leveraging CNC programming, these industries achieve not only high precision and efficiency but also the flexibility to innovate and customize products to meet evolving market demands and technical specifications.

Tips for Successful CNC Machine Programming

Be Grounded in the Basics

We must begin by ensuring a solid understanding of basic CNC programming codes and the functionality of CNC machines. Familiarity with the core aspects like G-code basics, machine controllers, and the operational characteristics of CNC machines forms the foundation of effective programming. This knowledge not only aids in troubleshooting but also enhances the ability to optimize and customize machine operations.

Customize Feed Rates

Adapting feed rates in real-time can significantly improve machining efficiency and part quality. For instance, if the cutting tool encounters a hard spot in the material, the feed rate can be adjusted to accommodate the increased resistance, preventing tool breakage and maintaining consistency. Modern CNC machines, like those from Haas, offer settings that automatically adjust the feed rate based on spindle load, which can be particularly useful in varying cutting conditions. Additionally, understanding how to manually adjust feed rates during operations, as seen in systems like UGS where feed rate adjustments can be made even while the g-code is running, is crucial for fine-tuning the machining process.

Take Compensation Types into Consideration

Cutter compensation is a critical feature in CNC programming, allowing for adjustments to the cutting path based on tool wear, deflection, and other factors. This feature helps maintain dimensional accuracy throughout the machining process, compensating for the tool’s physical changes over time. For example, using G-code commands like G41 and G42, programmers can instruct the machine to adjust the tool path for precise cuts, ensuring the end product meets the design specifications regardless of tool wear.

Make Programs Simple

Keeping CNC programs simple and straightforward can greatly enhance their reliability and ease of use. Documenting tool assemblies, machine setups, and CNC programs thoroughly ensures that each program can be run with minimal setup changes, reducing the risk of errors. Standardizing programming practices across the shop floor also helps maintain consistency, making it easier for operators to understand and execute programs. Moreover, using well-documented and proven feeds, speeds, and depth of cut values can streamline the programming process and improve the overall efficiency of production.

By integrating these strategies into CNC programming practices, we can significantly enhance the effectiveness and efficiency of CNC operations, leading to better quality parts and more streamlined manufacturing processes.

Through a thorough exploration of CNC programming, from its basics and types to the critical codes and software that drive its functionality, this article has laid a solid foundation for those seeking to navigate the complexities of this field. By delving into the systematic process of creating CNC code, its vital role across various industries, and offering practical tips for successful programming, we have underscored the significance of mastering CNC programming. It emerges not just as a technical skill but as a gateway to innovation, efficiency, and precision in the modern manufacturing landscape.

The imprints of CNC programming are evident across healthcare, consumer electronics, aerospace, and the automotive industry, showcasing its unparalleled contribution to precision, efficiency, and innovation. As we close this discussion, it becomes evident that continued advancements in CNC programming software and techniques are crucial for meeting the evolving demands of these industries. Emphasizing the importance of a solid understanding of CNC basics, adaptation to real-time machining needs, and simplicity in programming, empowers professionals to harness the full potential of CNC machines, paving the way for future technological breakthroughs in manufacturing.

FAQs

1. What does CNC programming entail?

CNC programming involves translating a 3D model of an object into a series of commands that a CNC machine can understand. These commands guide the CNC machine to automatically manufacture parts by removing material according to the design specifications.

2. What are the primary methods of programming a CNC machine?

There are three main approaches to CNC machine programming: manual, conversational, and CAM system programming. Manual programming requires the operator to input commands directly, which can be intricate and time-consuming. Conversational programming simplifies coding by using a more user-friendly interface, while CAM (Computer-Aided Manufacturing) programming utilizes software to create the machine instructions.

3. How can one learn CNC programming effectively?

The most effective way to learn CNC programming is through hands-on experience under the guidance of an experienced CNC operator. Consider seeking internships or employment opportunities in machine shops where CNC technology is used to gain practical knowledge and skills.

4. What is CNC and where is it used?

CNC, or computer numerical control, refers to a manufacturing process where pre-programmed software dictates the movement of factory tools and machinery. This technology is widely used in industries that involve metal and plastic production, enabling the execution of complex tasks in manufacturing.

Leave a Comment