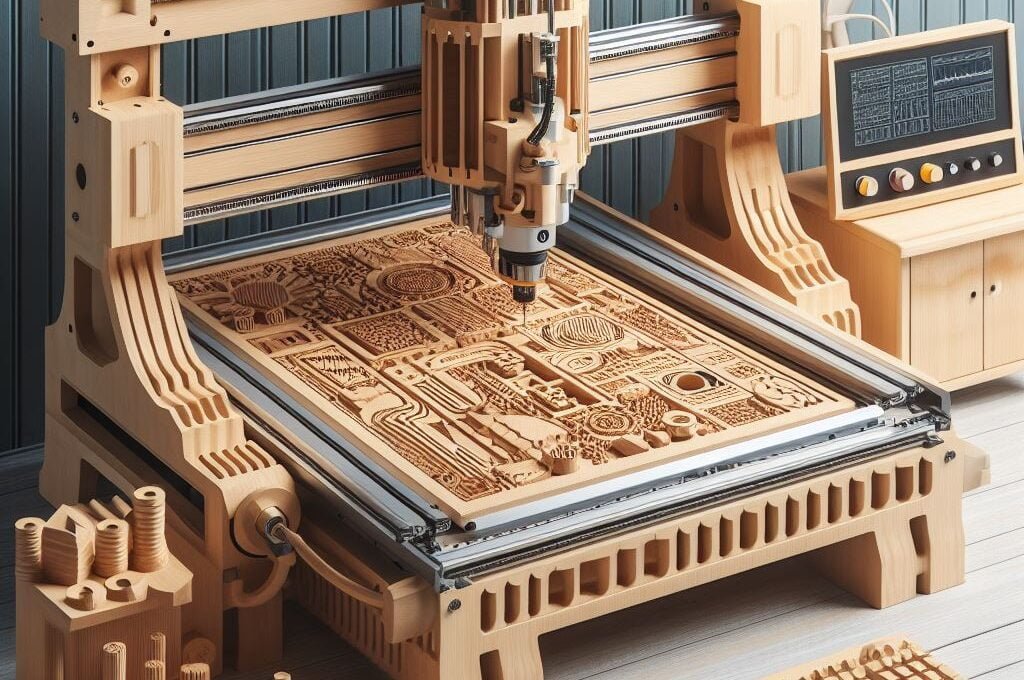

CNC machine wood carving is revolutionizing how we create intricate designs and patterns on wood, allowing for precise and intricate carvings with the push of a button 1. This technique is not limited to simple cuts but extends to complex relief carvings, demonstrating its versatility with examples like the stunning cherry wood pieces 2. Exploring the realm of CNC machine wood carvers opens up a universe of possibilities for both hobbyists and professionals alike. We delve into understanding CNC technology, evaluating top machines for woodworking, and ways to maximize their potential, ensuring your projects turn from good to exceptional 12.

Understanding CNC Machine Technology

CNC machine wood carving transforms the woodworking landscape with its unparalleled precision and efficiency. Here’s a closer look at the technology behind CNC machines:

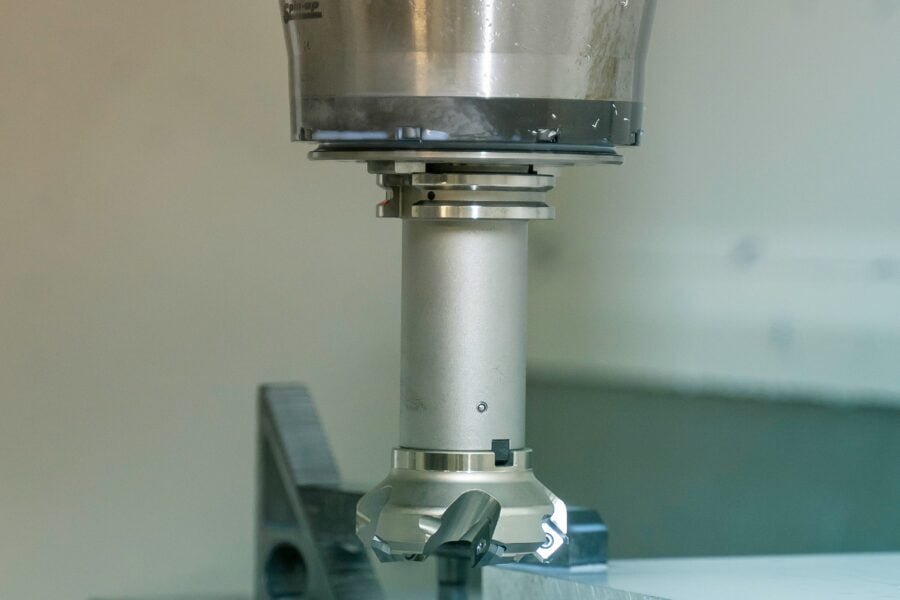

- Precision and Efficiency: CNC machines stand out for their ability to produce intricate and detailed carvings, far beyond what manual machines can achieve. This leads to enhanced productivity and scalability, with the added benefits of reduced labor costs. A single operator can manage multiple machines, cutting down on work hours and operational costs 1.

- Software and Operation: At the heart of CNC machines is G-code based software, which is automatically updated and requires minimal maintenance. This software aspect ensures a safe working environment and reduces costs associated with manual updates and checks. Operators find CNC machines user-friendly, with intuitive interfaces that require basic training to navigate. This simplicity in operation allows for intricate pattern engraving and cutting with ease 12.

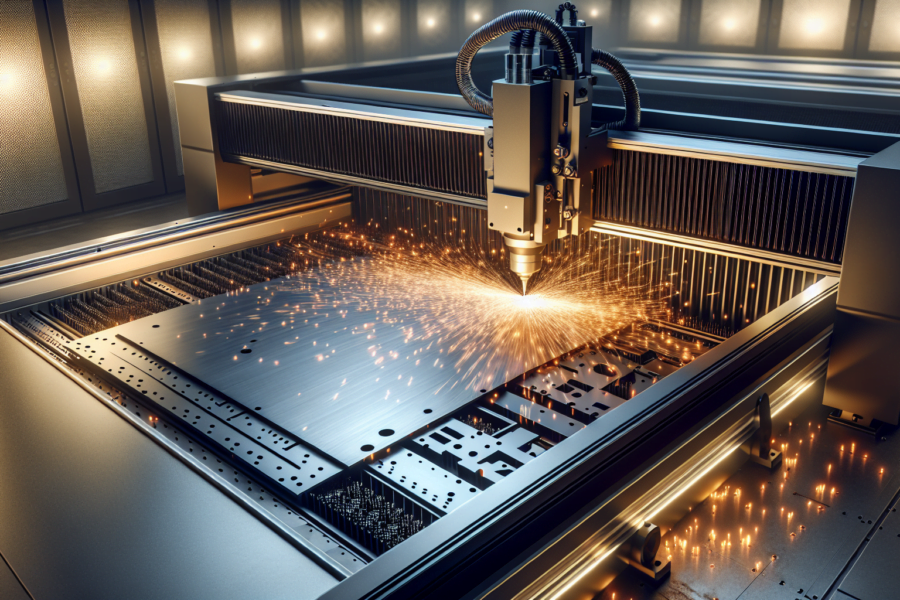

- Material Versatility and Applications: CNC machines are not limited to wood; they can work with a variety of materials including foam, stone, plastics, and metals. This versatility opens up a wide range of applications, from furniture making to sign making, and even intricate musical instruments. The spindle, a critical component, adjusts its speed to accommodate different materials, ensuring optimal cutting and engraving results. A sturdy machine base is crucial for accuracy, highlighting the importance of choosing quality equipment for precise and reliable outcomes 78.

By leveraging CNC machine wood technology, creators can unlock new levels of creativity and efficiency, producing work that meets modern industry demands with unparalleled precision.

Top CNC Machines for Woodworking

In exploring the top CNC machines for woodworking, a variety of options cater to different needs and skill levels. Here’s a closer look at some notable machines:

- Axiom Iconic-4 CNC Machine: This machine is well-suited for those who appreciate precision, featuring a 1-hp air-cooled spindle and ER collets for various bit sizes. Its auto on/off spindle and ball screws enhance efficiency, although it requires separate CAD/CAM software 13.

- Shapeoko Pro CNC Machine: Ideal for enthusiasts and professionals alike, it accepts any trim router with a 65mm-diameter motor. Notably, it includes Carbide Motion and Carbide Create 2-D CAD/CAM software, making it a comprehensive package despite the need for a separate router and Bitrunner accessory for auto functionality 13.

- Next Wave Shark HD500 CNC Machine: This machine stands out for its ability to accept a fourth axis and comes with VCarve Desktop software. It offers flexibility in router motor size and includes features like auto on/off for the router and optional dust shroud, though it does not come with a spoilboard 13.

Each of these machines has unique features designed to meet various woodworking needs, from hobbyist projects to more professional endeavors, ensuring there’s a CNC machine wood carver for every level of expertise and requirement.

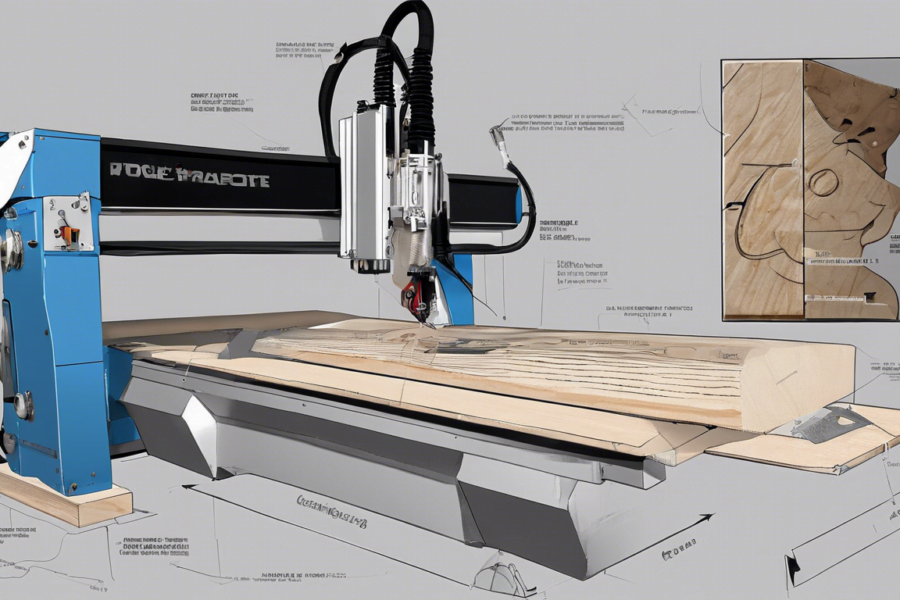

Choosing the Right CNC Machine for Your Projects

When embarking on the journey of choosing the right CNC machine for your projects, several factors come into play to ensure your creative endeavors are not just fruitful but also enjoyable. Here’s a breakdown to guide you through this process:

- Starting Essentials and Budgeting:

- Essential bits: Quarter-inch down cut, 60-degree v-groove, and a bowl and tray bit 6.

- For beginners, purchasing budget-friendly bits on Amazon is advisable due to the learning curve and potential for damage 6.

- As skills improve, investing in high-quality bits from reputable sources like andybirdbuilds.com ensures durability and precision 6.

- Materials and Tools:

- Machine Selection and Considerations:

- Evaluate workspace size to ensure the machine fits comfortably 14.

- Consider budget constraints, as CNC machines can range significantly in price 15.

- Research the machine’s specifications, focusing on cutting area, spindle power, and accuracy 16.

- Ensure software compatibility and accessibility to customer support and technical assistance 16.

- Look for machines with upgrade options to accommodate future growth 16.

Choosing the right CNC machine involves a balance between initial affordability and the potential for long-term growth and efficiency in your woodworking projects.

Maximizing Your CNC Machine’s Potential

Maximizing the potential of a CNC machine in woodworking involves a strategic approach to tool selection, programming, and operation. Here are key strategies:

- Tool Selection and Maintenance:

- Optimizing Machine Operation:

- Programming and Process Improvement:

- Regular Maintenance and Training:

- Monitoring and Safety:

By focusing on these areas, woodworkers can significantly enhance the efficiency and quality of their CNC machine operations.

Conclusion

Throughout this exploration of CNC machine wood carvers, we’ve delved into the intricacies of CNC technology, its transformative impact on woodworking, and the criteria for selecting and maximizing the potential of these sophisticated machines. The journey from understanding the foundational mechanics behind CNC machines to identifying the top models and effectively employing strategies for optimization highlights a dynamic landscape where precision, creativity, and efficiency converge. This comprehensive review not only serves as a guide for enthusiasts and professionals but also underscores the significant leap forward in crafting exquisite woodwork with unparalleled accuracy.

The implications of adopting CNC technology in woodworking reach far beyond individual projects, opening doors to innovative designs, streamlined production processes, and the potential for expanding creative horizons. As we look toward the future, the continued advancement of CNC machines promises even greater opportunities for enhancing the art and science of woodworking. Embracing these tools requires a commitment to learning and adapting, but the rewards in terms of quality, productivity, and satisfaction are immeasurable. As the field evolves, so too will the capabilities and achievements of those who harness the power of CNC machine wood carvers in their craft.

FAQs

Can You Earn Income from Operating a Wood CNC Machine?

Yes, you can generate income by producing finished products or by providing CNC woodworking services and workshops. This option is particularly appealing for those interested in mastering the craft or seeking help with their DIY woodworking projects.

What Types of Wood Are Ideal for CNC Carving?

The optimal woods for CNC machining include Beech, Oak, Walnut, Yew, Cedar, Cypress, and Fir. Fir is noted for its ease of handling and uniform wood patterns, while Pine stands out for its lightweight nature, pale color, and surprising resistance to shrinking due to its hardness.

How Challenging Is It to Construct Your Own CNC Machine?

Building a CNC machine varies in difficulty. Assembling a CNC router from a complete kit is on the easier side of the spectrum, whereas constructing one from scratch presents more challenges. It’s important to choose your approach wisely to avoid disappointment. Additionally, setting up dust extraction and an enclosure may require extra effort after the machine is built.

Is CNC Machining Part of Woodworking?

Yes, CNC machining is a significant component of modern woodworking. It involves the use of advanced machinery, controlled by computers, to measure and cut wood accurately. This technology is utilized in both residential and industrial settings to produce various materials and shapes.

References

[1] – https://www.biesse.com/in/wood/magazine/blog/benefits-of-cnc-wood-carving-machine [2] – https://shop.snapmaker.com/blogs/snapmaker/top-benefits-of-using-cnc-wood-carving-machine [3] – https://www.niharindustries.com/benefits-using-cnc-wood-carving-machine/ [4] – https://www.igoldencnc.com/the-advantages-of-cnc-wood-carving-machine.html [5] – https://awinet.org/is-cnc-used-in-woodworking/ [6] – https://www.youtube.com/watch?v=ktARgAkZFrw [7] – https://www.youtube.com/watch?v=2L-JUhO-Y0M [8] – https://www.biesse.com/in/wood/magazine/blog/guide-to-choose-cnc-machines [9] – https://www.3erp.com/manufacturing-technology/cnc-machining/ [10] – https://www.youtube.com/watch?v=54D1IGBMw_E [11] – https://www.lincolntech.edu/news/skilled-trades/cnc-machining-and-manufacturing/what-is-a-cnc-machine [12] – https://www.youtube.com/watch?v=lEyNWtM6MW4 [13] – https://www.woodmagazine.com/tool-reviews/a-buyers-guide-to-benchtop-cnc-machines [14] – https://community.carbide3d.com/t/best-option-for-a-total-beginner/66616 [15] – https://woodweb.com/knowledge_base/Advice_on_Choosing_a_CNC_Router.html [16] – https://www.bobscnc.com/blogs/news/hoow-to-select-the-best-cnc-router-for-your-shop [17] – https://www.quora.com/Whats-the-method-that-must-been-applied-to-choose-the-right-tool-in-the-CNC-router-machine [18] – https://www.stylecnc.com/user-manual/How-to-improve-cnc-wood-router-work-efficiency.html [19] – https://www.linkedin.com/pulse/10-tips-help-improve-efficiency-productivity-cnc-machines [20] – https://www.youtube.com/watch?v=nsEo5F4tllo [21] – https://www.harveyperformance.com/in-the-loupe/achieving-success-in-cnc-woodworking/

Leave a Comment