Computer Numerical Control (CNC) tools have revolutionized the machining industry by providing precise, automated control over machining processes. These tools are integral to modern manufacturing, enabling the production of complex and high-precision parts with remarkable consistency. At their core, CNC tools operate through pre-programmed sequences of machine control commands, allowing for intricate operations that would be impossible or highly impractical with manual machining methods. (CNC tools list)

The role of CNC tools in the industry cannot be overstated. They are pivotal in achieving superior machining efficiency, maintaining quality standards, and ensuring overall project success. A well-curated CNC tools list is essential for any manufacturing setup, as it directly impacts the speed and accuracy of the machining processes. From milling cutters and lathes to plasma cutters and laser engravers, each tool on the CNC tools list has its specific applications and advantages.

Selecting the right CNC tools for a particular task is crucial. The choice of tools affects various facets of the machining process, including material removal rates, surface finish quality, and tool longevity. For instance, using an inappropriate tool can lead to suboptimal machining performance, increased wear and tear, and even damage to the workpiece. Conversely, the right tool can significantly enhance productivity, reduce waste, and ensure that the final product meets stringent quality standards.

Understanding the diverse range of CNC tools and their respective functionalities is fundamental for machinists and engineers. It empowers them to make informed decisions that align with specific project requirements, thereby optimizing operational efficiency. As we delve deeper into this guide, we will explore various types of CNC tools, their unique features, and the latest innovations that continue to drive the industry forward.

Essential CNC Tools List

Understanding the essential CNC tools list is critical for anyone involved in machining tasks. These tools are indispensable for achieving precision, efficiency, and versatility in various projects. Here, we outline a comprehensive array of CNC tools, each described by its function and common applications.

First and foremost, end mills are a staple in any CNC toolkit. These tools are used for milling operations, including profiling, slotting, and contouring. They come in various shapes and sizes, catering to different materials and project needs. High-speed steel (HSS) and carbide end mills are popular choices due to their durability and cutting efficiency.

Next on the list are drill bits. These tools are essential for creating precise holes in a workpiece. Available in a variety of diameters and lengths, drill bits can be customized for specific tasks. Materials like cobalt and carbide enhance their performance, particularly in challenging conditions.

Face mills are another crucial tool for CNC machining. Primarily used for face milling operations, these tools are designed to remove large amounts of material quickly. They are ideal for flattening surfaces and achieving a smooth finish. Their cutting inserts can be replaced, making them a cost-effective option.

Reamers are precision tools used for enlarging and finishing pre-drilled holes. They ensure an accurate diameter and a smooth internal surface finish, making them indispensable for high-tolerance applications. Reamers are typically made from HSS or carbide.

Tapping tools are specialized for creating internal threads in holes. They come in various forms, including hand taps and machine taps, each suited to different threading tasks. High-quality materials like vanadium and tungsten carbide maximize their longevity and performance.

Lathe tools, such as turning and boring tools, are essential for shaping materials on a lathe. These tools can perform a range of operations, from rough cutting to fine finishing. Carbide-tipped lathe tools are preferred for their durability and precision.

Lastly, tool holders are vital for securing CNC tools in place during operations. They ensure stability and precision, reducing the risk of tool deflection and enhancing overall machining accuracy. Common types include collet chucks, end mill holders, and drill chucks.

By familiarizing yourself with this essential CNC tools list, you can ensure your toolkit is well-equipped for a variety of machining tasks. Each tool plays a specific role in the machining process, contributing to the overall success and efficiency of your projects.

Types of CNC Tools

The world of CNC machining is vast and diverse, featuring a wide array of tools designed to meet various manufacturing needs. Understanding the types of CNC tools available is crucial for optimizing production processes and achieving precise results. Below, we explore some of the most commonly used CNC tools, each with its specific applications and benefits.

End Mills are among the most versatile CNC tools. They come in various shapes, each suited for different tasks. Flat end mills are ideal for cutting slots, profiling, and face milling. Ball nose end mills are used for 3D contouring and machining complex surfaces, while corner radius end mills provide a combination of the flat end and ball nose benefits, offering increased strength and reduced wear.

Drills are essential for creating holes in materials. Twist drills are the most common, known for their efficiency in general drilling tasks. Center drills are used to create a starting point for a larger drill bit, ensuring accuracy and preventing the bit from wandering. Spot drills serve a similar purpose, mainly used to create a dimple that guides the twist drill.

Taps and Dies are specialized CNC tools used for creating threads. Taps cut female threads inside a hole, while dies cut male threads on a rod. These tools are indispensable in manufacturing threaded components with high precision.

Reamers are employed to enlarge and finish previously drilled holes to a precise diameter, ensuring a smooth and accurate finish. They are ideal for applications requiring tight tolerance and high surface quality.

Countersinks are used to create a conical hole to allow the head of a screw or bolt to sit flush with or below the surface of the material. This is crucial in applications requiring a smooth, unbroken surface.

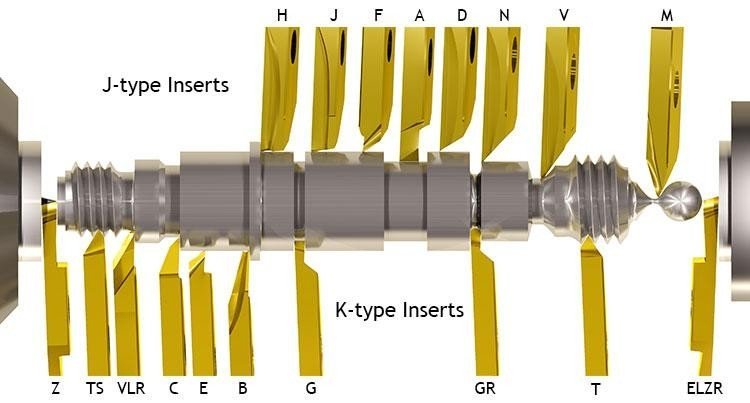

Inserts and Indexable Tools are designed for efficiency and cost-effectiveness. Inserts are replaceable cutting edges that can be rotated or flipped to reveal a new, sharp edge, extending the tool’s life. Indexable tools, such as indexable end mills and drills, offer the advantage of quick insert changes, reducing downtime and maintaining consistent performance.

Understanding the comprehensive CNC tools list and their specific functions can significantly improve machining efficiency, product quality, and overall production outcomes. By selecting the appropriate tool for each task, manufacturers can ensure optimal performance and longevity of their CNC machines.

CNC Tool Materials

CNC tools are crafted from a variety of materials, each offering distinct advantages and attributes. The selection of the appropriate CNC tool material is crucial for optimizing tool life, cutting speed, and machining efficiency. Among the most commonly used materials are High-Speed Steel (HSS), carbide, ceramic and CBN (Cubic Boron Nitride), and diamond-coated tools.

High-Speed Steel (HSS) is a versatile material that combines toughness, wear resistance, and the ability to withstand high temperatures. HSS tools are commonly used for general machining applications, particularly when working with softer materials like mild steel and aluminum. They are also relatively inexpensive, making them ideal for smaller-scale operations or where budget constraints are a concern.

Carbide tools are known for their exceptional hardness and heat resistance, allowing them to maintain a sharp cutting edge for longer periods. These tools are suitable for high-speed machining and are often used for cutting harder materials such as stainless steel and cast iron. Carbide tools come in various grades, each tailored for specific applications, and offer a significant improvement in productivity and tool life compared to HSS tools.

Ceramic and CBN tools are designed for high-speed and high-temperature machining. Ceramic tools excel in cutting superalloys and other hard materials due to their superior hardness and thermal stability. CBN tools, on the other hand, are ideal for machining hardened steels and cast irons, providing excellent wear resistance and prolonged tool life. Both materials can significantly increase machining efficiency but come at a higher cost compared to HSS and carbide tools.

Diamond-coated tools represent the pinnacle of cutting tool technology. Their extreme hardness and low friction coefficient make them perfect for precision machining of non-ferrous materials such as aluminum alloys, plastics, and composites. Diamond-coated tools offer unparalleled longevity and performance, especially in abrasive environments. However, their high cost limits their use to specialized applications where maximum precision and tool life are paramount.

Choosing the right material from the CNC tools list is essential for achieving optimal machining performance. Factors such as the type of material being machined, desired tool life, and cutting speeds should all be considered to ensure the best results.

Tool Holders and Accessories

In CNC machining, the selection of appropriate tool holders is paramount to achieving precision and efficiency. Tool holders serve as the critical interface between the machine and the cutting tool, ensuring stability and accuracy during operation. The types of tool holders commonly used in CNC machining include collet chucks, end mill holders, and shrink fit holders. Each type has distinct characteristics that make it suitable for specific applications.

Collet chucks, for instance, are widely recognized for their versatility and ability to grip a wide range of tool shank sizes. They are particularly effective in high-speed machining where precision is crucial. End mill holders, on the other hand, are designed for holding end mills and are known for their robust clamping force, making them ideal for heavy-duty cutting tasks. Shrink fit holders utilize thermal expansion to achieve a secure and precise grip on the tool, which is beneficial for high-precision machining tasks.

Apart from tool holders, essential accessories such as tool changers and coolant delivery systems play a significant role in enhancing machining operations. Automatic tool changers (ATCs) streamline the machining process by swiftly swapping out tools without manual intervention, thereby reducing downtime and increasing productivity. Coolant delivery systems, on the other hand, are integral in maintaining optimal cutting temperatures and prolonging tool life. By directing coolant precisely to the cutting area, these systems help in dissipating heat, reducing wear, and improving surface finish quality.

Incorporating the right mix of tool holders and accessories into your cnc tools list can significantly impact machining performance. The synergy between these components ensures that tools are held securely, changes are made efficiently, and the cutting environment is kept optimal. As CNC technology continues to advance, the development of innovative tool holders and accessories will further contribute to achieving higher levels of precision and efficiency in machining operations.

Specialty CNC Tools

Specialty CNC tools are designed to perform specific tasks that standard tools might not handle efficiently or with the required precision. These tools include thread mills, thread forming tools, engraving tools, CNC lathe tools such as turning, facing, grooving, threading tools, and micro tools for precision machining. Understanding the unique features and applications of these tools is crucial for optimizing your CNC tools list and ensuring high-quality results.

Thread mills are used for creating threads in a workpiece. Unlike traditional taps, thread mills can produce threads without the need for a pilot hole, making them suitable for both internal and external threading. This tool is particularly advantageous for creating threads in hard materials or in applications where precision and thread quality are critical.

Thread forming tools, on the other hand, are ideal for creating threads by deforming the material rather than cutting it. This process results in stronger threads with a smoother surface finish, reducing the risk of thread failure. These tools are typically used in applications requiring high-strength threads, such as in the automotive and aerospace industries.

Engraving tools are specialized CNC tools used for detailed work, such as marking parts, creating intricate designs, or adding text to a workpiece. These tools come in various shapes and sizes, allowing for a wide range of applications from simple text engraving to complex artistic designs.

CNC lathe tools are essential for turning operations. Turning tools are used for the outer diameter of a workpiece, while facing tools are used to create a flat surface on the end of the workpiece. Grooving tools cut narrow channels, and threading tools create precise threads. Each of these tools plays a vital role in shaping and finishing cylindrical parts with high precision.

Micro tools are designed for precision machining tasks that require extreme accuracy. These tools are used in applications such as electronics, medical devices, and intricate mold making. Their small size allows for the creation of detailed features and tight tolerances, which are crucial in high-precision industries.

Incorporating these specialty CNC tools into your CNC tools list can significantly enhance the efficiency and quality of your machining processes. By understanding when and why to use each tool, you can make informed decisions that lead to better outcomes and optimized production workflows.

Tool Selection Guide

Selecting the right tools for CNC machining is vital to achieving precision and efficiency in any manufacturing process. The first step in creating a comprehensive CNC tools list is understanding the specific requirements of the material being machined. Different materials, such as metals, plastics, and composites, have unique characteristics that influence tool selection.

When machining metals, for example, high-speed steel (HSS) and carbide tools are often preferred for their durability and ability to withstand high temperatures. In contrast, plastics may require tools with specific geometries to prevent melting or deformation. Composites, known for their abrasive nature, often necessitate diamond-coated tools to maintain sharpness and reduce wear.

Tool geometry is another critical factor to consider. The shape and angle of the tool’s cutting edge directly impact the machining process. For instance, end mills with varying flute designs can optimize chip removal and surface finish, depending on the machining operation. Similarly, tools with a higher rake angle can reduce cutting forces and improve material removal rates.

Specific machining operations also guide tool selection. Drilling, milling, turning, and engraving each have distinct requirements. For drilling, selecting the appropriate drill bit size and type (e.g., twist drills, step drills) ensures accuracy and efficiency. Milling operations benefit from tools like ball nose end mills for contouring and flat end mills for slotting.

To optimize tool performance, consider factors such as feed rates, cutting speeds, and coolant use. Adjusting these parameters can significantly enhance tool longevity and machining quality. Regular tool maintenance, including cleaning and inspection for wear, is also crucial to maintaining consistent performance.

By carefully considering these factors, machinists can create an effective CNC tools list tailored to their specific needs, ensuring optimal results and operational efficiency.

Tool Maintenance and Care

Effective maintenance and care of CNC tools are pivotal in ensuring their longevity and optimal performance. Implementing a consistent maintenance routine can significantly enhance machining quality while also reducing overall operational costs. Here are some best practices for maintaining CNC tools that can be easily integrated into your workflow.

Firstly, regular inspection is crucial. Examine CNC tools for signs of wear and tear before and after each use. Look for indicators such as dull edges, chipping, or unusual wear patterns. These signs suggest that the tool might need sharpening or replacement. Utilizing a CNC tools list can help keep track of the condition and maintenance schedule for each tool, ensuring no tool is overlooked.

Another essential aspect is proper lubrication. Keeping the tools and the CNC machine well-lubricated reduces friction and wear, thereby extending the tool’s life. Make sure to use the appropriate lubricant recommended by the tool manufacturer. Regularly clean the tools and the machine to remove any debris or build-up that could interfere with performance. Consistent cleaning and lubrication can prevent corrosion and other damage, ensuring smoother operation.

Storage also plays a crucial role in tool maintenance. Store CNC tools in a clean, dry environment to protect them from moisture and contaminants. Using protective cases or designated tool holders can prevent accidental damage and make it easier to organize and access the tools when needed.

Finally, knowing when to replace tools is essential. While sharpening can extend a tool’s life, there comes a point when replacement is more cost-effective. Tools that frequently dull or damage workpieces, even after sharpening, should be retired and replaced. Keeping a well-maintained cnc tools list can help identify patterns of wear and determine the optimal replacement schedule.

By adhering to these maintenance practices, you can ensure that your CNC tools remain in top condition, thereby enhancing productivity and machining quality. Proper care not only extends the life of your tools but also contributes to more efficient and cost-effective operations.

Innovations in CNC Tooling

The realm of CNC tooling has seen remarkable advancements in recent years, driven by the need for increased efficiency, precision, and durability. One of the most significant developments is the introduction of new materials and coatings that significantly enhance tool performance. For instance, carbide tools, renowned for their hardness and wear resistance, are now often coated with advanced materials like titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC). These coatings not only extend the tool’s lifespan but also improve its cutting speed and accuracy, thereby optimizing the overall machining process.

Another innovation reshaping the CNC tools list is the advent of high-performance ceramics and cermets. These materials offer exceptional thermal stability and resistance to deformation at high temperatures, making them ideal for high-speed machining applications. Additionally, the use of polycrystalline diamond (PCD) and cubic boron nitride (CBN) tools has gained traction, especially in industries requiring ultra-precise machining of hard and abrasive materials.

Looking ahead, the future of CNC tooling appears poised for further transformation with the integration of smart technologies. The incorporation of sensors and IoT (Internet of Things) capabilities into CNC tools is emerging as a game-changer. These smart tools can monitor their own wear and tear, predict maintenance needs, and even adjust operational parameters in real-time to maintain optimal performance. This level of automation and self-diagnosis not only reduces downtime but also enhances productivity and quality control.

Moreover, advancements in additive manufacturing are beginning to influence CNC tooling. The ability to 3D print custom tools tailored to specific applications allows for unprecedented flexibility and rapid prototyping. This innovation not only reduces lead times but also enables the production of complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods.

In summary, the continuous evolution of CNC tooling, driven by new materials, coatings, and smart technologies, is set to significantly impact the machining industry. These innovations promise to deliver higher efficiency, greater precision, and enhanced tool longevity, ultimately pushing the boundaries of what is possible in modern manufacturing. As the CNC tools list expands and adapts to these advancements, businesses stand to gain substantial competitive advantages in an increasingly demanding market.

Top Brands and Manufacturers

When navigating the extensive landscape of CNC tools, recognizing the top brands and manufacturers is pivotal for making well-informed decisions. Several industry leaders have established their reputations through consistent innovation, quality, and reliability. This segment delves into a comparison of these premier brands, evaluating their offerings, strengths, and potential drawbacks.

One of the most recognized names in the CNC tool industry is Mazak. Renowned for their advanced technology and robust machinery, Mazak’s CNC tools list includes everything from multi-tasking machines to horizontal machining centers. Their tools are praised for high precision, durability, and cutting-edge software integration. However, their premium quality often comes with higher costs, which might be a significant consideration for small-scale operations.

Haas Automation is another heavyweight in the CNC sector. Known for their user-friendly controls and cost-effective solutions, Haas machines are a favorite among various industries. Their extensive service network and reliable customer support further enhance their appeal. Although Haas boasts affordability, some users report limitations in customization and advanced features compared to higher-end brands.

DMG Mori stands out for its innovative engineering and comprehensive CNC tools list, which includes some of the most technologically advanced machines in the market. DMG Mori tools are celebrated for their efficiency and precision, making them suitable for complex manufacturing tasks. The downside, however, is the significant investment required, which might not be feasible for all businesses.

User reviews play a crucial role in understanding real-world performance. For instance, operators frequently commend the reliability and ease of use offered by Okuma CNC tools. Okuma’s machines are also noted for their excellent thermal stability and precision. Nevertheless, some users indicate that their interface can be challenging to master initially.

Finally, Sandvik Coromant is acclaimed for its cutting tools and solutions, providing exceptional performance and sustainability. Their tools are particularly favored in the aerospace and automotive industries for their material versatility and wear resistance. Despite their superior quality, the cost of Sandvik tools can be prohibitive for smaller enterprises.

In conclusion, selecting the right CNC tools involves balancing between cost, functionality, and specific needs. By considering the strengths and weaknesses of these top brands, users can make informed decisions that align with their operational requirements and budget constraints.

Cost-Effective Tooling Solutions

For small businesses, managing the costs associated with CNC tooling can be a significant challenge. However, there are several strategies that can help in reducing tooling expenses without sacrificing quality. To begin with, opting for high-quality yet affordable CNC tools can make a notable difference. It’s crucial to maintain a well-rounded CNC tools list that includes cost-effective options which do not compromise on performance or durability.

One effective approach is to invest in multi-functional tools. These tools can perform various tasks, reducing the need for multiple specialized tools and thus cutting down overall costs. For instance, a combination tool that can perform both drilling and milling can be a valuable addition to any CNC tools list, providing versatility and efficiency.

Another tactic is to regularly maintain and sharpen tools. Proper maintenance extends the lifespan of tools and ensures consistent performance, minimizing the frequency of replacements. Using tool holders and collets that ensure a secure fit can also prevent tool wear and tear, further contributing to cost savings.

Balancing cost and quality is paramount. It’s advisable to conduct thorough research and read reviews before making a purchase. Sometimes, lower-cost tools from lesser-known brands can offer comparable quality to their more expensive counterparts. Participating in industry forums or consulting with other professionals can provide insights into affordable yet reliable CNC tool brands.

Additionally, considering the total cost of ownership rather than just the initial purchase price can lead to more cost-effective decisions. This includes evaluating factors such as tool longevity, maintenance requirements, and potential downtime caused by tool failures. Choosing tools that offer a good balance of upfront cost and long-term savings can ultimately provide better value for money.

In conclusion, small businesses can effectively manage CNC tooling costs by selecting multi-functional tools, ensuring proper maintenance, and balancing cost with quality. By integrating these strategies into their CNC tools list, businesses can enhance productivity while keeping expenses in check.

CNC Tool Libraries and Management

Setting up an effective CNC tool library is a fundamental step in optimizing machining processes. A well-structured CNC tools list serves as a centralized repository of all the tools at your disposal, including specifications, usage history, and maintenance records. This comprehensive database not only streamlines the selection of appropriate tools for various tasks but also ensures that each tool is used efficiently and safely.

One of the primary benefits of an organized tool library is enhanced machining efficiency. When every tool is cataloged and easily accessible, operators can quickly identify and retrieve the necessary equipment, thereby reducing setup times and minimizing downtime. This streamlined process is crucial in high-volume production environments where time saved translates directly into cost savings.

Software solutions play a pivotal role in modern CNC tool management. Advanced tool management systems offer features such as automated tool tracking, usage analytics, and predictive maintenance alerts. These systems can integrate with existing CNC machining software, providing real-time updates and ensuring that the CNC tools list remains current and accurate. By leveraging these technologies, machinists can anticipate wear and tear, schedule timely maintenance, and avoid unexpected breakdowns that could disrupt production schedules.

Furthermore, a well-maintained CNC tool library fosters better inventory control. Keeping an up-to-date inventory helps in monitoring tool usage patterns and planning for replacements or upgrades. This proactive approach not only reduces the risk of running out of critical tools but also enables more informed decision-making regarding tool investments and budget allocations.

In summary, the strategic organization and management of a CNC tools list are vital for maximizing operational efficiency and maintaining consistent production quality. By utilizing modern software solutions and adhering to best practices, manufacturers can ensure that their tool libraries contribute to smoother workflows and enhanced productivity.

Case Studies and User Stories

Real-world applications of CNC machinery demonstrate the importance of selecting the right tools from the CNC tools list to ensure optimal performance and efficiency. One notable case study involves a mid-sized manufacturing company that sought to enhance its production capabilities. By integrating a diverse range of CNC tools, such as end mills, drill bits, and lathe tools, the company was able to significantly reduce production time while maintaining high precision in their output.

Another example comes from a custom automotive parts manufacturer. The company faced challenges in producing complex components that required intricate detailing. Through meticulous selection of CNC tools like ball nose cutters and carbide inserts, they achieved superior surface finishes and minimized material wastage. This not only improved product quality but also resulted in cost savings and higher customer satisfaction.

User stories also reveal valuable insights into the practical aspects of CNC tool utilization. A seasoned machinist shared their experience of transitioning from traditional machining methods to CNC technology. They emphasized the importance of understanding the capabilities and limitations of each tool on the CNC tools list. This knowledge allowed them to select the most appropriate tools for different tasks, leading to enhanced productivity and reduced tool wear.

Testimonials from industry professionals further underscore the significance of effective tool selection. One professional highlighted the impact of using high-speed steel (HSS) tools for cutting softer materials and carbide tools for harder substrates. This strategic approach not only extended tool life but also optimized machine performance, illustrating the crucial role of informed decision-making in CNC operations.

These case studies and user stories collectively illustrate how the thoughtful selection and application of CNC tools can drive success in various manufacturing scenarios. By leveraging the right tools from a comprehensive CNC tools list, businesses can achieve remarkable improvements in efficiency, precision, and overall production quality.

Educational Resources and Training for CNC Tooling

To master the intricacies of CNC tooling, a wealth of educational resources is available for both beginners and seasoned professionals. These resources cover a broad spectrum of learning mediums, from online courses to hands-on workshops, providing comprehensive knowledge on the cnc tools list and their applications.

Online courses are a popular choice for learning about CNC tools. Websites like Coursera, Udemy, and LinkedIn Learning offer various courses that range from introductory to advanced levels. These courses often include video lectures, interactive quizzes, and practical assignments to solidify understanding. For those seeking more formal education, institutions like MIT and Stanford provide open courseware on CNC machining and related subjects.

Workshops and hands-on training programs are invaluable for gaining practical experience with CNC tools. Local community colleges, technical schools, and specialized training centers frequently host workshops that allow participants to work directly with CNC machines. These programs are designed to cover fundamental topics such as machine setup, tool selection, and maintenance, ensuring that attendees develop a solid practical foundation.

Books remain an essential resource for in-depth learning. Titles like “CNC Programming Handbook” by Peter Smid and “CNC Machining Handbook” by James Madison offer detailed explanations and are highly regarded in the industry. These books provide comprehensive insights into CNC programming, machine operation, and tool usage, making them indispensable for anyone looking to deepen their understanding of CNC tooling.

Blogs and forums also play a significant role in the continuous education of CNC professionals. Websites like CNC Cookbook and Practical Machinist host blogs and forums where experts share tips, troubleshooting advice, and updates on the latest innovations in CNC tools. Engaging with these platforms allows learners to stay informed about industry trends and connect with a community of like-minded individuals.

Certifications and formal training programs are crucial for validating one’s skills and knowledge in CNC tooling. Recognized certifications, such as those offered by the National Institute for Metalworking Skills (NIMS) and the Manufacturing Skill Standards Council (MSSC), provide a benchmark of competency. These certifications typically involve rigorous testing and are highly respected by employers, enhancing career prospects in the CNC industry.

In conclusion, a diverse array of educational resources is available for those eager to expand their expertise in CNC tooling. From online courses and hands-on workshops to authoritative books and interactive forums, these resources offer invaluable knowledge and practical skills that are essential for mastering the CNC tools list and staying competitive in the industry.

Common Challenges and Troubleshooting

Operating CNC tools can present various challenges that may affect both precision and efficiency. One common issue is tool wear, which can lead to inaccuracies in machining. Regular inspection and timely replacement of tools are crucial to maintaining performance. Additionally, using the correct tool for specific materials can significantly reduce wear and improve longevity.

Another prevalent challenge is tool breakage, often caused by incorrect feed rates and spindle speeds. Ensuring that these parameters are correctly set according to the material and tool specifications is essential. Utilizing manufacturer’s guidelines for feed rates and spindle speeds can prevent breakage and extend the life of the CNC tools list. (CNC Tune for Instagram)

Vibration and chatter are also frequent issues that can compromise the quality of the final product. These can be mitigated by ensuring the rigidity of the workpiece setup and choosing appropriate cutting parameters. Furthermore, using high-quality, balanced tools can reduce the likelihood of vibration.

Tool deflection is another problem that can affect the accuracy of CNC machining. This occurs when the tool bends under cutting forces, resulting in dimensional errors. To avoid this, ensure that the tool length is minimized and the tool diameter is maximized for the application. Additionally, employing tool holders that provide better rigidity can also help in reducing deflection.

Coolant management is critical in CNC operations. Inadequate coolant flow can lead to overheating, affecting both tool life and workpiece quality. Regular maintenance of the coolant system and using the appropriate type and concentration of coolant can mitigate this issue.

Lastly, ensuring proper chip evacuation is vital to prevent tool damage and ensure smooth operation. Using tools designed for effective chip removal and maintaining clean machine interiors can help in managing this challenge.

By understanding these common challenges and implementing best practices for troubleshooting, operators can enhance the performance and lifespan of their CNC tools, ultimately achieving better machining results.

Leave a Comment