End mill cutters are essential tools in CNC machining, designed specifically for cutting and shaping materials with precision and efficiency. These versatile tools are characterized by their ability to perform a variety of milling operations, making them indispensable in the modern manufacturing landscape. Unlike traditional cutting tools such as drills and reamers, end mill cutters can handle complex tasks like milling slots, pockets, and intricate shapes with ease, providing a higher level of flexibility and accuracy in the machining process.

The primary function of an end mill cutter is to remove material from a workpiece to create the desired shape or feature. This is achieved through the tool’s flutes, which are helical grooves that run along the length of the cutter. These flutes facilitate the cutting action while also helping to evacuate chips from the cutting zone, ensuring a smooth and efficient operation. End mill cutters come in various shapes, sizes, and materials, each designed for specific applications and material types, further enhancing their utility in diverse manufacturing scenarios.

One of the key advantages of end mill cutters over traditional tools is their ability to cut in multiple directions. While drills are limited to axial cuts and reamers are used primarily for finishing holes, end mill cutters can perform lateral (side) cutting as well, allowing for a broader range of machining operations. This multi-directional cutting capability reduces the need for tool changes and increases productivity, making end mill cutters a cost-effective solution for many manufacturing processes.

In modern manufacturing, the importance of end mill cutters cannot be overstated. Their precision, versatility, and efficiency make them a preferred choice for producing high-quality components in industries ranging from aerospace to automotive. As CNC machining technology continues to advance, the role of end mill cutters in achieving superior machining performance and product quality remains crucial, cementing their status as a cornerstone of contemporary manufacturing practices.

Types of End Mill Cutters

End mill cutters are a crucial component in CNC machining, and their varied designs are tailored to specific applications. Understanding the distinctions between different types of end mill cutters can significantly enhance machining efficiency and product quality.

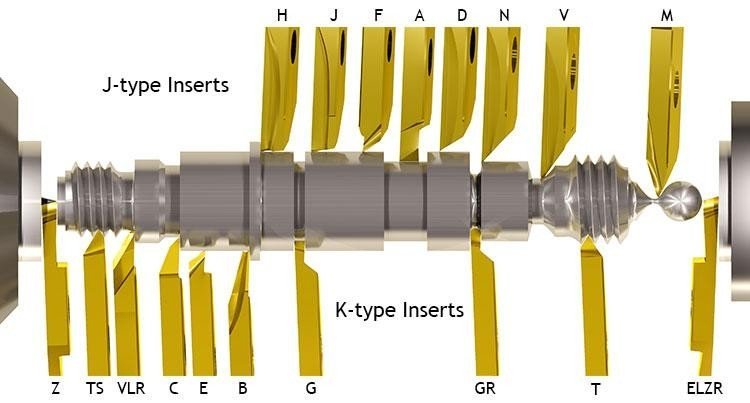

Flat End Mills: Flat end mills, also known as square end mills, feature straight cutting edges that produce sharp, unrounded corners. These cutters are ideal for general milling tasks such as slotting, profiling, and face milling. The flat end mill’s design allows it to remove substantial amounts of material quickly, making it suitable for roughing operations. Its versatility makes it a staple in any machinist’s toolkit.

Ball Nose End Mills: Ball nose end mills have a hemispherical tip that is engineered for precision contouring and 3D machining. These cutters are indispensable for complex surface profiles and detailed finishing work. The rounded end minimizes the risk of gouging, providing a smoother finish on intricate parts. Ball nose end mills excel in applications requiring high accuracy, such as mold making and die sinking.

Corner Radius End Mills: Corner radius end mills combine the features of flat and ball nose end mills. They have a flat cutting edge with a rounded corner, which enhances the cutter’s strength and reduces chipping. This design is particularly useful for milling operations involving high-stress areas and where edge wear is a concern. The added durability makes corner radius end mills preferable for heavy-duty and high-speed machining.

Specialty End Mills: In addition to the common types, there are specialty end mills designed for specific tasks. Roughing end mills, for instance, have serrated cutting edges that allow for rapid material removal, reducing machining time. Tapered end mills possess a conical shape that is ideal for creating angled, precise features such as dovetails and chamfers. These specialty tools enhance the versatility and capability of CNC machines, enabling them to tackle a broader range of machining challenges.

Overall, selecting the appropriate end mill cutter is fundamental to optimizing machining processes, ensuring that the right tool is matched to the specific requirements of each task.

Factors to Consider When Selecting End Mill Cutters

Choosing the appropriate end mill cutter for specific machining tasks is critical for achieving optimal performance and tool longevity. One of the primary considerations is material compatibility. The cutter material, such as High-Speed Steel (HSS) or carbide, must align with the workpiece material. For instance, while HSS is suitable for softer materials like aluminum and plastics, carbide end mill cutters are preferred for harder metals due to their superior wear resistance and greater hardness.

Flute geometry is another crucial factor. The number of flutes, helix angle, and flute length significantly impact chip evacuation and surface finish. End mill cutters with fewer flutes, such as two or three, offer better chip clearance and are ideal for softer materials. Conversely, cutters with higher flute counts, like four or more, are used for harder materials and provide a finer surface finish. The helix angle, which typically ranges from 30 to 45 degrees, influences the cutting action and chip evacuation. A higher helix angle improves surface finish and cutting efficiency but may require more power.

The choice of coating on end mill cutters also plays a pivotal role in extending tool life and enhancing performance. Common coatings include Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Titanium Aluminum Nitride (TiAlN). TiN coating is well-suited for general-purpose machining, offering increased hardness and wear resistance. TiCN provides superior performance in milling operations involving harder materials, while TiAlN excels in high-temperature applications, making it ideal for cutting harder metals at higher speeds.

Lastly, tool dimensions such as cutter diameter, length, and shank diameter must be carefully considered. The cutter diameter determines the width of the cut and influences the tool’s rigidity. A larger diameter offers increased rigidity but may require more power. The overall length of the cutter affects reach and stability, with longer cutters potentially introducing more deflection. The shank diameter should match the collet or tool holder to ensure a secure fit, preventing tool slippage and enhancing precision.

Applications and Industries Using End Mill Cutters

End mill cutters are indispensable tools in the realm of CNC machining, playing a crucial role in a variety of applications. These versatile cutting tools are predominantly used for tasks such as facing, profiling, and pocketing. Facing involves the creation of a flat surface on the workpiece, while profiling enables the shaping of intricate contours and geometries. Pocketing, on the other hand, entails the removal of material from a specific area to create cavities or recesses.

Different industries leverage the unique capabilities of end mill cutters to enhance their manufacturing processes. In the aerospace industry, precision and consistency are paramount. End mill cutters, particularly those made from high-performance materials, are employed to machine complex components like turbine blades and structural parts. The ability to produce intricate shapes with tight tolerances ensures the reliability and safety of aerospace components.

The automotive industry also relies heavily on end mill cutters for producing engine parts, transmission components, and custom body parts. The use of specialized end mills allows for high-speed machining, improving productivity and reducing production costs. The versatility of these tools supports the fabrication of both prototype and mass-produced parts, catering to the industry’s diverse needs.

Mold making is another sector where end mill cutters are extensively used. Precision molds for plastic injection molding and die-casting require intricate details and smooth finishes. End mills, particularly ball nose end mills, are ideal for achieving the fine surface finishes and detailed contours necessary in mold production. These tools enable manufacturers to produce high-quality molds that meet stringent industry standards.

In the medical industry, the demand for precision and miniaturization is ever-increasing. End mill cutters are utilized to machine medical devices, implants, and surgical instruments. The ability to work with biocompatible materials and achieve precise dimensions ensures the functionality and safety of medical products. Advanced end mills with coatings and geometries tailored for specific materials enhance the efficiency and quality of medical device manufacturing.

Overall, the diverse applications and industry-specific uses of end mill cutters underscore their importance in modern manufacturing. By selecting the appropriate end mill cutter for each task, manufacturers can achieve optimal performance, precision, and efficiency in their production processes.

Advantages and Benefits of End Mill Cutters

End mill cutters stand out in the realm of CNC machining for their exceptional precision and accuracy, making them indispensable for tasks requiring tight tolerances and complex geometries. Leveraging advanced technology, these cutters enable machinists to create intricate designs with remarkable fidelity, significantly reducing the margin of error. The ability to achieve such high levels of precision ensures that end mill cutters are particularly suited for industries where exact specifications are non-negotiable, such as aerospace, medical device manufacturing, and automotive sectors.

One of the most compelling benefits of end mill cutters is their versatility. Unlike single-purpose tools, end mill cutters can perform multiple operations, including drilling, slotting, contouring, and profiling. This multifaceted capability reduces the need for tool changes, leading to increased productivity and workflow efficiency. Manufacturers can achieve complex machining tasks with a single tool, thereby simplifying the machining process and minimizing downtime.

Efficiency is another hallmark of end mill cutters. These tools are designed to facilitate faster material removal rates (MRR), making them ideal for high-speed machining applications. The enhanced MRR not only shortens cycle times but also improves the overall throughput of the machining process. Additionally, end mill cutters contribute to superior surface finishes, which is crucial for components that require minimal post-processing. The improved surface finish is achieved through the cutter’s ability to maintain consistent contact with the material, resulting in smoother and more refined surfaces.

In summary, the advantages and benefits of end mill cutters in CNC machining are multifaceted. Their precision and accuracy make them indispensable for intricate designs, while their versatility reduces the need for multiple tools. Enhanced efficiency in material removal and superior surface finishes further solidify their role as essential tools in modern manufacturing environments. By integrating end mill cutters into their processes, manufacturers can achieve higher quality outcomes and greater operational efficiency.

Maintenance and Care of End Mill Cutters

Proper maintenance and care of end mill cutters are essential for extending their lifespan and ensuring optimal performance. Regular cleaning is a crucial step in this process. After each use, it’s important to remove any built-up debris, including chips and coolant residues, which can impact the cutter’s efficiency and precision. Utilizing a soft brush or compressed air can effectively clear these materials without causing damage to the cutter’s surface.

Storage is another critical factor in maintaining end mill cutters. Storing these tools in a dry, controlled environment prevents rust and corrosion. Ideally, cutters should be kept in their original cases or specially designed tool holders that protect the cutting edges from contact with other tools or surfaces. This precaution helps maintain the sharpness of the cutting edges, which is vital for high-quality machining results.

Regular inspection of end mill cutters is necessary to identify wear and damage. Visual inspection should focus on detecting any signs of chipping, rounding of cutting edges, or discoloration, which may indicate overheating. Additionally, using a magnifier can help in identifying micro-cracks or fractures that are not visible to the naked eye. Implementing a routine inspection schedule can prevent extensive damage and reduce the need for frequent replacements.

Sharpening and regrinding are essential maintenance practices that can restore the efficiency of end mill cutters. Professional sharpening services utilize precision grinding machines to accurately resharpen the cutting edges, ensuring that the tool performs as intended. For those with the necessary equipment and expertise, in-house sharpening can be a cost-effective alternative. However, it’s important to adhere to the manufacturer’s specifications to avoid altering the tool geometry, which could negatively impact performance.

By following these maintenance and care guidelines, you can significantly enhance the durability and functionality of your end mill cutters. Consistent cleaning, proper storage, diligent inspection, and periodic sharpening will ensure that these essential tools continue to deliver high-quality results in your CNC machining operations. (CNC Tune for Instagram)

Common Issues and Troubleshooting

In the realm of CNC machining, end mill cutters play a pivotal role. However, their performance can be hindered by several common issues. Understanding these problems and their solutions is essential for maintaining efficiency and ensuring high-quality outputs.

One prevalent issue with end mill cutters is tool breakage. This can be caused by various factors including improper feed rates, excessive cutting speeds, and incorrect tool selection. To prevent tool breakage, it is crucial to ensure that the feed rate and cutting speed are appropriately matched to the material being machined. Additionally, selecting the right type of end mill cutter for the specific operation can significantly reduce the likelihood of breakage. Regular inspection and timely replacement of worn-out tools also play a critical role in prevention.

Poor surface finishes are another common problem encountered during machining operations. This can result from dull tools, incorrect cutting parameters, or inappropriate tool paths. To improve surface finish quality, it is essential to use sharp end mill cutters and optimize cutting parameters such as speed, feed rate, and depth of cut. Employing a proper tool path strategy can also enhance surface finish by minimizing tool marks and ensuring a smooth transition between passes.

Chatter and vibration are detrimental to both the tool and the workpiece, leading to poor quality and reduced tool life. These issues often arise due to insufficient rigidity in the machine setup, excessive tool overhang, or inappropriate cutting conditions. To minimize chatter and vibration, ensure that the machine setup is as rigid as possible, with minimal tool overhang. Adjusting the cutting parameters, such as reducing the depth of cut or altering the spindle speed, can also help mitigate these problems. Additionally, using end mill cutters with variable helix angles can disrupt the harmonic frequencies that cause chatter, leading to more stable machining operations.

By addressing these common issues through proper troubleshooting and preventive measures, the performance and longevity of end mill cutters can be significantly enhanced, resulting in more efficient and high-quality CNC machining processes.

Innovations and Trends in End Mill Cutter Technology

Recent advancements in end mill cutter technology have significantly elevated the performance and efficiency of CNC machining. One of the most notable trends is the adoption of new materials and composites in the construction of end mill cutters. High-performance materials such as carbide, cobalt alloys, and advanced ceramics provide superior hardness and heat resistance, enabling end mill cutters to handle more demanding machining tasks with greater precision and longevity.

Another crucial development is in the realm of coatings. Modern end mill cutters are often coated with advanced materials like Titanium Aluminum Nitride (TiAlN) and Diamond-Like Carbon (DLC), which substantially enhance their durability and cutting efficiency. These coatings reduce friction, minimize heat buildup, and protect the cutter from wear and tear, making them an essential feature for high-speed and high-precision machining operations.

The integration of smart tooling and Industry 4.0 technologies has also begun to transform end mill cutter design and usage. By embedding sensors within the cutters, real-time data can be collected and analyzed to monitor tool wear, temperature, and cutting forces. This information can then be utilized to optimize machining processes, predict maintenance needs, and enhance overall productivity. The Internet of Things (IoT) and data analytics play pivotal roles in this transformation, enabling seamless communication between machines and facilitating data-driven decision-making in manufacturing environments.

Additionally, adaptive control systems are being incorporated into CNC machines to adjust cutting parameters dynamically based on real-time feedback from smart end mill cutters. This synergized approach not only improves machining accuracy but also extends the tool life, reducing downtime and operational costs.

Overall, these innovations in end mill cutter technology are driving the evolution of CNC machining, ensuring that manufacturers can meet the increasingly complex and precise demands of modern production with greater efficiency and reliability.

Safety Considerations When Using End Mill Cutters

Ensuring safety when using end mill cutters is paramount for both operators and equipment. The first step in maintaining a safe working environment is the appropriate use of personal protective equipment (PPE). Operators should wear safety glasses to protect their eyes from flying debris and metal shavings. Additionally, hearing protection is necessary in noisy environments to prevent hearing damage. Gloves, although useful, should be chosen carefully to avoid entanglement in moving parts.

Safe operating practices are essential when handling and setting up end mill cutters in CNC machines. Before commencing any operation, it is crucial to perform a thorough inspection of the end mill cutter for any signs of wear, damage, or contamination. A damaged cutter can compromise the quality of the workpiece and pose a significant safety risk. Proper clamping and securing of the workpiece and the cutter in the machine are fundamental to prevent movement during machining, which could lead to accidents.

Operators must also be trained in the correct procedures for setting up and operating CNC machines. This includes understanding the machine’s control interface, programming parameters, and emergency stop functions. Regular maintenance of the machine and the end mill cutters enhances performance and reduces the likelihood of mechanical failures. It is advisable to follow the manufacturer’s guidelines for tool life and replacement intervals to prevent unexpected breakages.

In the event of an accident or tool failure, having clear and accessible emergency procedures is vital. Operators should know how to quickly shut down the machine and safely remove any broken parts or workpieces. First aid kits should be readily available, and all personnel should be trained in basic first aid and emergency response protocols. Reporting and documenting accidents can help in analyzing the causes and implementing measures to prevent future occurrences.

By adhering to these safety considerations, operators can minimize risks and ensure a safe and efficient working environment when using end mill cutters in CNC machining.

Conclusion and Future Outlook

Throughout this comprehensive guide, we have explored the various facets of end mill cutters and their integral role in CNC machining. From their structural composition and material selection to their diverse applications in industries such as aerospace, automotive, and manufacturing, end mill cutters demonstrate unparalleled versatility and precision. Their ability to create intricate designs and achieve high levels of accuracy underscores their importance in modern machining processes.

One of the key benefits of using end mill cutters is their capability to perform a wide range of operations, including milling, drilling, and contouring. This multifunctionality not only enhances productivity but also reduces the need for multiple tools, thereby lowering costs and streamlining operations. Additionally, advancements in coating technologies and material compositions have significantly extended the lifespan of end mill cutters, leading to improved efficiency and reduced downtime.

Looking ahead, the future of end mill cutter technology appears promising, driven by continuous innovations and evolving machining practices. Emerging trends such as the integration of artificial intelligence and machine learning in CNC machining promise to further enhance the precision and efficiency of end mill cutters. These technologies can optimize tool paths, predict tool wear, and recommend optimal cutting conditions, thereby maximizing the performance of end mill cutters.

Moreover, the development of advanced materials, including nanocomposites and high-performance alloys, is expected to push the boundaries of what end mill cutters can achieve. These materials offer increased durability and heat resistance, making them ideal for high-speed and high-temperature applications. As industries continue to demand higher precision and efficiency, the evolution of end mill cutter technology will undoubtedly play a pivotal role in meeting these challenges.

In summary, end mill cutters are indispensable tools in the realm of CNC machining, offering a blend of versatility, precision, and efficiency. As technology continues to advance, we can anticipate even greater innovations in end mill cutter design and functionality, paving the way for more sophisticated and efficient machining solutions.

Additional Resources and References

For those seeking to delve deeper into the world of end mill cutters and CNC machining, there are numerous resources available that offer comprehensive insights and advanced knowledge. Below are some meticulously curated recommendations for books, articles, and websites, as well as information on relevant training courses, workshops, and certifications.

Books:

“CNC Programming Handbook” by Peter Smid is an excellent resource that covers a wide range of topics, including the intricate details of end mill cutters. Another valuable book is “Machining Fundamentals” by John R. Walker, which provides practical insights into the operation and application of various cutting tools.

Articles and Journals:

For scholarly articles, the “Journal of Manufacturing Processes” frequently publishes research on advancements in end mill cutter technologies and their applications in CNC machining. Additionally, “Modern Machine Shop” magazine offers articles that discuss the latest trends and innovations in tooling and machining processes.

Websites:

Online platforms such as CNC Cookbook (cnccookbook.com) offer a plethora of articles, tutorials, and videos specifically focused on end mill cutters and CNC machining. Another useful site is Machinery’s Handbook (machinerys-handbook.com), which serves as a comprehensive reference for machining professionals.

Training Courses and Workshops:

Numerous institutions provide specialized training on CNC machining and end mill cutters. For instance, the Society of Manufacturing Engineers (SME) offers various courses and workshops that cover the fundamentals and advanced concepts of CNC machining. Similarly, online platforms like Coursera and Udemy have courses that allow learners to gain practical knowledge and skills in CNC machining and tooling.

Certifications:

Certifications can significantly enhance one’s expertise and credibility in the field. The National Institute for Metalworking Skills (NIMS) offers certification programs that cover different aspects of machining, including the use of end mill cutters. These certifications are recognized within the industry and can be valuable for career advancement.

By exploring these resources, individuals can gain a deeper understanding of end mill cutters, stay updated with the latest advancements, and enhance their skills in CNC machining.

Leave a Comment