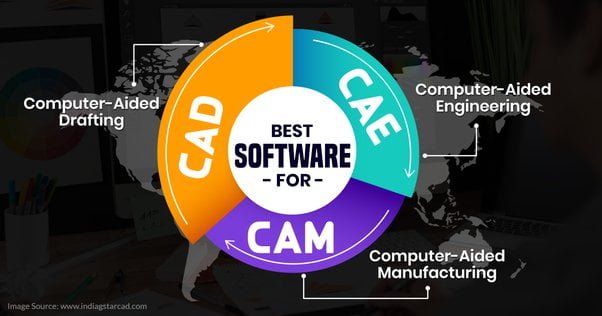

Computer-Aided Manufacturing (CAM) software is an indispensable component in the realm of modern manufacturing. It facilitates the automation of machining processes, thereby streamlining production workflows and significantly enhancing operational efficiency. At its core, CAM software translates digital designs into precise instructions for Computer Numerical Control (CNC) machines. This integration enables manufacturers to produce complex parts with high precision and consistency.

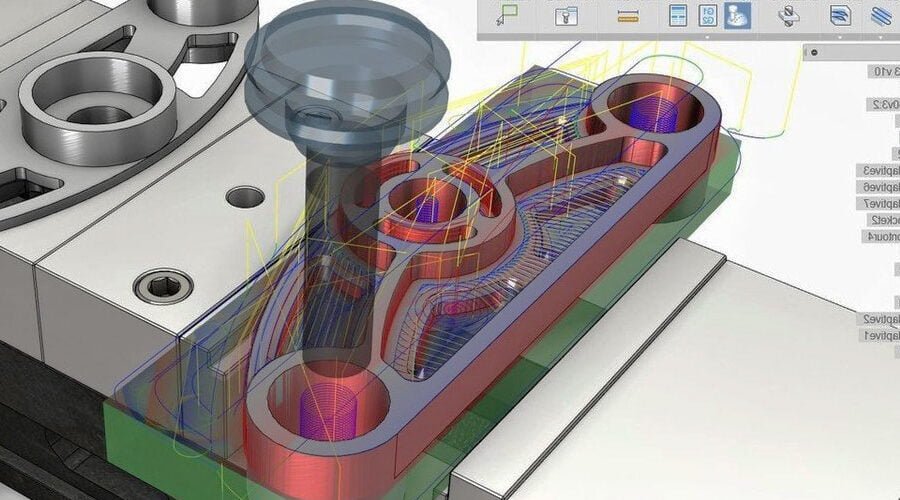

The primary function of CAM software is to convert CAD (Computer-Aided Design) models into toolpaths—sequences of movements that CNC machines follow to shape raw materials into finished products. By automating this process, CAM software reduces the likelihood of human error, ensuring that each part is machined to exact specifications. This not only improves the quality of the final product but also minimizes waste and optimizes the use of materials.

One of the key advantages of utilizing the best CAM software is its ability to boost productivity. By automating repetitive tasks and enabling machines to operate continuously, manufacturers can achieve higher output rates without compromising on quality. Furthermore, CAM software enhances precision by allowing for intricate and complex designs that would be challenging to execute manually. This precision is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the smallest deviations can have significant consequences.

In addition to improving efficiency and precision, CAM software also plays a critical role in optimizing manufacturing workflows. It allows for better planning and scheduling of machining operations, ensuring that resources are utilized effectively. By providing real-time feedback and simulations, CAM software helps manufacturers identify potential issues before they arise, thereby reducing downtime and maintenance costs.

In summary, CAM software is a vital tool that integrates seamlessly with CNC machines to enhance efficiency, precision, and productivity in modern manufacturing environments. By leveraging the capabilities of the best CAM software, manufacturers can stay competitive in an increasingly demanding market, delivering high-quality products with greater speed and accuracy.

Top CAM Software Programs

In the realm of modern manufacturing, choosing the right CAM (Computer-Aided Manufacturing) software is crucial for efficiency and precision. Among the leading options, Mastercam, Fusion 360, and SolidWorks CAM stand out due to their robust features and user-friendly interfaces. This section delves into these top CAM software programs to help you determine which might be the best fit for your needs.

Mastercam is renowned for its comprehensive suite of tools that cater to both novice users and experienced professionals. It offers advanced machining capabilities, extensive toolpath options, and a vast library of post-processors. Users appreciate its powerful simulation features that facilitate error-free manufacturing. Mastercam’s strong community support and regular updates further enhance its appeal, making it a top choice for many industries.

Fusion 360, developed by Autodesk, is celebrated for its integrated CAD, CAM, and CAE capabilities. This cloud-based software provides seamless collaboration features, allowing multiple users to work on a project simultaneously. Fusion 360 excels in ease of use and offers a range of functionalities from basic design to complex machining. Its affordability and the flexibility of subscription plans make it accessible to small businesses and startups, solidifying its position as one of the best CAM software options available.

SolidWorks CAM integrates directly with SolidWorks CAD, streamlining the design-to-manufacturing process. It is particularly valued for its rule-based machining, which automates repetitive tasks, thereby reducing programming time. SolidWorks CAM’s intuitive interface and robust simulation tools ensure that users can quickly generate and verify toolpaths. This software is highly regarded for its efficiency and precision, making it a preferred choice among engineers and designers.

Each of these CAM software programs offers unique strengths tailored to different aspects of manufacturing. Whether you prioritize advanced machining, collaborative capabilities, or streamlined workflows, understanding these features will guide you in selecting the best CAM software for your specific requirements.

Best CAM Software for Different Industries

In the realm of modern manufacturing, different industries have unique challenges and requirements that necessitate specialized CAM software solutions. The aerospace manufacturing sector, for instance, demands a high level of precision and the ability to handle complex geometries. For this industry, software like Mastercam and Siemens NX often lead the way. Mastercam is renowned for its user-friendly interface and powerful toolpath generation, making it an excellent choice for cutting-edge aerospace components. Siemens NX, on the other hand, offers integrated CAD/CAM capabilities, which streamline the design-to-production process, ensuring that intricate aerospace parts meet stringent quality standards.

In automotive production, efficiency and speed are paramount. Delcam PowerMILL and Autodesk Fusion 360 emerge as top contenders in this sector. Delcam PowerMILL is celebrated for its high-speed machining capabilities, which significantly reduce production times without compromising on accuracy. Its advanced simulation features help in verifying toolpaths, thus minimizing errors and enhancing overall productivity. Autodesk Fusion 360, with its cloud-based platform, offers a collaborative environment where design and manufacturing teams can work seamlessly. This software’s flexibility and comprehensive toolset make it ideal for the dynamic and fast-paced automotive industry.

The medical device industry, characterized by strict regulatory standards and the necessity for precision, benefits greatly from CAM software like SolidCAM and GibbsCAM. SolidCAM, known for its iMachining technology, provides optimized toolpaths that ensure high-quality finishes on medical components. Its integration with SolidWorks facilitates a smooth transition from design to manufacturing, critical for producing complex medical devices. GibbsCAM, with its intuitive interface and robust milling capabilities, supports the production of intricate parts that meet the medical field’s stringent requirements. Its ability to handle multi-task machining processes enhances its suitability for the medical device industry.

Ultimately, the best CAM software for any industry hinges on its specific needs and production goals. By leveraging the strengths of specialized CAM solutions, industries can achieve higher efficiency, precision, and overall better outcomes in their manufacturing processes.

Criteria for Selecting CAM Software

Choosing the right CAM (Computer-Aided Manufacturing) software is a critical decision for modern manufacturing operations. The first and foremost consideration is the user interface and ease of use. An intuitive interface significantly reduces the learning curve, allowing operators to become proficient in using the software more quickly. Look for CAM software that offers customizable toolbars, clear menu structures, and comprehensive help documentation to facilitate smoother operations.

Compatibility with existing CNC (Computer Numerical Control) machinery and CAD (Computer-Aided Design) software is another crucial factor. Ensuring that the best CAM software integrates seamlessly with your current systems can save both time and resources. Pay attention to the file formats supported by the CAM software, and verify that it can import and export files compatible with your current CAD software. Additionally, check if the software supports post-processors for your specific CNC machines, as this ensures that the generated tool paths are accurately translated into machine instructions.

The cost versus value of the CAM software is also an important consideration. While it might be tempting to opt for the least expensive option, it is essential to evaluate the software’s features and capabilities against its price. Considerations should include the software’s ability to handle complex geometries, the availability of advanced machining strategies, and the quality of customer support. In many instances, investing a bit more in robust software can result in significant long-term savings through improved efficiency and reduced downtime.

Practical tips for making an informed decision include requesting demos or trial versions of the CAM software you are considering. This hands-on experience allows you to evaluate the software’s performance in real-world scenarios. Additionally, seek feedback from other users in your industry to understand their experiences and any potential pitfalls. By meticulously assessing these factors, you can select the best CAM software that aligns with your manufacturing needs and advances your operational capabilities.

Advanced Features in CAM Software

Modern CAM software has evolved significantly to incorporate advanced features that greatly enhance manufacturing capabilities. One pivotal feature is multi-axis machining, which allows for complex parts to be created with higher precision and reduced manual intervention. Multi-axis machining capabilities in the best CAM software enable the simultaneous movement of various machine axes, making it possible to produce intricate geometries that would be otherwise challenging with traditional methods.

Another key feature is adaptive toolpath strategies. These strategies optimize the cutting path based on real-time analysis of the material and cutting conditions. By dynamically adjusting the toolpath, CAM software can minimize machining time, reduce tool wear, and improve surface finish. This level of adaptability ensures that the manufacturing process is both efficient and cost-effective, providing significant advantages over static toolpath strategies.

Real-time simulation and verification are also critical components of modern CAM software. These features allow manufacturers to visualize the machining process in a virtual environment before actual production begins. By simulating the tool movements and verifying the toolpath, potential errors can be identified and corrected early in the process. This not only enhances precision but also reduces the risk of costly mistakes, ensuring that the final product meets the required specifications.

Integration with CAD software is another advanced feature that streamlines the manufacturing workflow. Seamless integration allows for the direct import and use of CAD models within the CAM environment, facilitating a more cohesive design-to-manufacturing process. This integration reduces the need for redundant data entry and ensures that design changes are automatically updated in the CAM software, maintaining consistency and accuracy throughout the production cycle.

Incorporating these advanced features, the best CAM software significantly boosts productivity and precision in modern manufacturing. By leveraging multi-axis machining, adaptive toolpath strategies, real-time simulation and verification, and seamless CAD integration, manufacturers can achieve higher efficiency, reduced production times, and superior product quality.

User Guides and Tutorials

Understanding the intricacies of CAM software can significantly enhance the efficiency and precision of manufacturing processes. For beginners, starting with user guides that offer step-by-step instructions is crucial. These guides typically cover basic operations such as setting up the software, creating a simple design, and executing a basic machining operation. Popular CAM software like Fusion 360, Mastercam, and SolidCAM provide comprehensive user manuals that are invaluable for new users.

For more experienced users, advanced techniques and tips can unlock the full potential of the best CAM software. These advanced guides delve into complex topics such as multi-axis machining, toolpath optimization, and post-processing customization. By mastering these advanced features, users can achieve higher productivity and more precise results. Additionally, many CAM software vendors offer forums and communities where users can share their insights and solutions, fostering a collaborative learning environment.

Video tutorials are another excellent resource for both novices and seasoned professionals. Visual demonstrations can make complex concepts easier to grasp and can provide practical insights into the software’s real-world applications. Many CAM software providers host YouTube channels where they regularly upload tutorial videos covering a wide range of topics. For instance, Autodesk’s Fusion 360 channel features videos that range from introductory lessons to advanced project walkthroughs, catering to users of all skill levels.

To further aid in learning, it’s beneficial to follow along with these tutorials using the actual software. This hands-on approach allows users to immediately apply what they’ve learned, reinforcing their understanding and skill development. Additionally, some platforms offer interactive courses that include quizzes and assignments, providing a structured learning path.

Incorporating these resources into your learning regimen can significantly enhance your proficiency with CAM software, enabling you to leverage its full capabilities in modern manufacturing environments.

Case Studies and Success Stories

Real-world examples offer invaluable insights into the practical applications and benefits of CAM software in modern manufacturing. By examining these case studies, we can better understand how various businesses have leveraged the best CAM software to enhance their operational efficiency, accuracy, and overall productivity.

One notable success story involves a mid-sized aerospace component manufacturer. This company faced significant challenges with maintaining tight tolerances and meeting stringent industry standards. By integrating advanced CAM software into their production workflow, they achieved remarkable improvements. The software enabled precise control over complex machining processes, significantly reducing wastage and rework. As a result, they reported a 25% increase in production efficiency and a 30% reduction in material costs within the first year of implementation.

Another compelling example is a custom automotive parts manufacturer that specialized in producing small batches of highly customized components. The traditional manual programming methods they relied upon were time-consuming and prone to errors. Transitioning to a robust CAM software solution revolutionized their operations. The software’s intuitive interface and powerful simulation tools allowed for rapid prototyping and error-free production. This not only shortened their product development cycle by 40% but also enhanced the precision of the final products, earning them a reputation for exceptional quality.

In the medical device manufacturing sector, a company focused on producing intricate surgical instruments used CAM software to tackle the intricacies of their designs. The software’s advanced toolpath generation capabilities allowed them to create complex geometries with impeccable accuracy. This led to a 20% increase in production speed and a significant improvement in the consistency of their products. The ability to quickly adapt to design changes also facilitated faster time-to-market for their innovative medical solutions.

These case studies vividly demonstrate how the best CAM software can drive transformative changes across diverse industries. By streamlining processes, enhancing precision, and reducing costs, CAM software proves to be an essential tool in modern manufacturing, enabling businesses to achieve their goals and maintain a competitive edge.

CAM Software for Specific Applications

Computer-Aided Manufacturing (CAM) software has become an indispensable tool in modern manufacturing, offering tailored solutions for various specific applications. One critical area where CAM software excels is in prototyping and small-batch production. For businesses involved in developing prototypes, the best CAM software provides the precision and flexibility needed to rapidly iterate designs. This software allows manufacturers to optimize tool paths and minimize material waste, which is crucial for cost-effective prototyping. Moreover, features like real-time simulation and error detection significantly reduce the risk of costly mistakes.

In the realm of large-scale manufacturing, CAM software proves to be equally invaluable. Production environments that handle high-volume outputs require robust and reliable software solutions to manage complex machining processes. The best CAM software for large-scale manufacturing integrates seamlessly with automated machinery, ensuring consistent and high-quality production. These systems often include advanced scheduling and resource management tools, which help manufacturers maintain efficiency and meet tight deadlines. Additionally, many CAM solutions offer comprehensive reporting features that provide insights into production metrics, helping businesses to continually improve their processes.

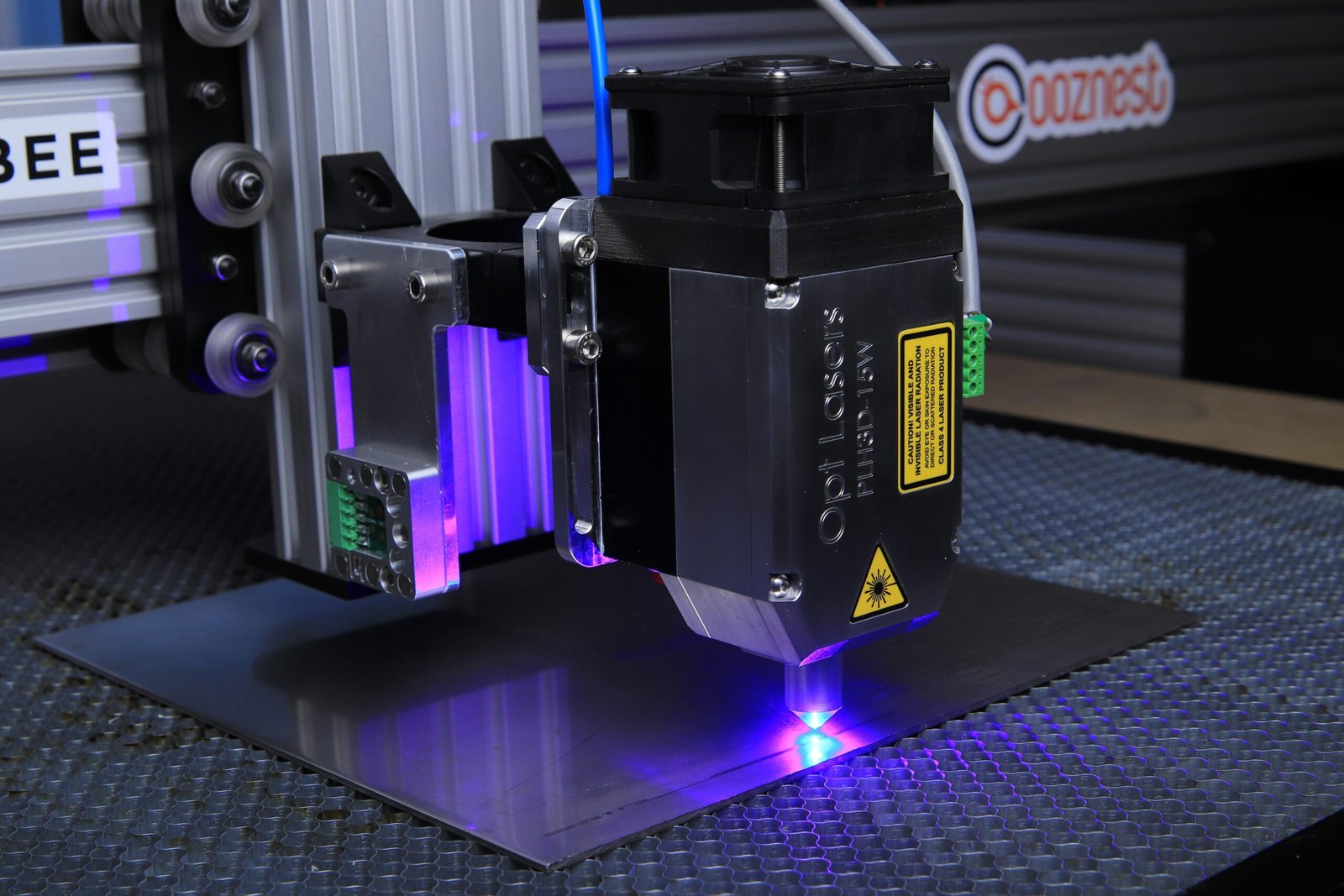

Another rapidly growing application of CAM software is in 3D printing. The integration of CAM software with 3D printing technology opens up new possibilities for innovative manufacturing techniques. The best CAM software for 3D printing enables precise control over layer deposition, ensuring that intricate geometries and complex structures are accurately produced. This is particularly important for industries such as aerospace and medical device manufacturing, where precision and reliability are paramount. Furthermore, CAM software can streamline the transition from digital design to physical object, making it easier to bring new products to market efficiently.

In summary, CAM software caters to a wide range of manufacturing applications, from prototyping and small-batch production to large-scale manufacturing and 3D printing integration. By leveraging the best CAM software, manufacturers can enhance their operational efficiency, reduce costs, and produce high-quality products tailored to their specific needs. (CNC Tune for Instagram)

Emerging Trends in CAM Software

In the rapidly evolving landscape of modern manufacturing, Computer-Aided Manufacturing (CAM) software continues to undergo significant advancements. Among the most notable emerging trends is the integration of artificial intelligence (AI) and machine learning. These technologies are revolutionizing the best CAM software by offering enhanced automation and optimization capabilities. AI-driven CAM systems can now predict tool wear, optimize tool paths, and adjust machining parameters in real-time, leading to increased efficiency and reduced downtime.

Another significant trend is the shift towards cloud-based CAM solutions. Cloud computing offers numerous advantages, including improved collaboration, scalability, and access to advanced computational resources. By leveraging the cloud, manufacturers can perform complex simulations and analyses more efficiently. This trend is particularly beneficial for small and medium-sized enterprises (SMEs) that may not have access to high-end computational infrastructure.

Additionally, the integration of Internet of Things (IoT) technologies is becoming increasingly prevalent in CAM software. IoT-enabled devices provide real-time data from the manufacturing floor, enabling more informed decision-making and predictive maintenance. This connectivity ensures that the best CAM software can offer a more holistic view of the production process, leading to improved quality control and resource management.

Customization and flexibility are also key trends in the development of CAM software. Modern manufacturing demands highly specialized solutions tailored to specific industry needs. Consequently, CAM software providers are focusing on modular and customizable platforms that allow users to adapt the software to their unique requirements. This approach enhances the overall user experience and ensures that the software can keep pace with rapidly changing market demands.

Furthermore, the rise of additive manufacturing, commonly known as 3D printing, is influencing CAM software development. As additive manufacturing techniques become more widespread, CAM software is evolving to support these new processes. This includes the ability to generate tool paths for various 3D printing technologies and materials, ensuring seamless integration into existing manufacturing workflows.

Open Source vs. Commercial CAM Software

The debate between open-source and commercial CAM software is a pivotal consideration for manufacturers aiming to optimize their production processes. Each type of software offers distinct advantages and disadvantages, catering to varied needs and resources. Understanding these differences can significantly influence the selection of the best CAM software for specific applications.

Open-source CAM software is often lauded for its cost-effectiveness, as it typically requires no licensing fees. This aspect can be particularly advantageous for small businesses or startups operating on limited budgets. Additionally, open-source solutions offer a high degree of flexibility and customizability. Users can modify the source code to tailor the software to their unique requirements, which can lead to innovative and highly specialized manufacturing processes.

However, open-source CAM software also presents certain challenges. The absence of dedicated customer support can be a significant drawback, especially for users who lack extensive technical expertise. While online communities and forums can provide some assistance, the reliability and timeliness of such support might not match that of commercial alternatives. Furthermore, open-source software may lag in terms of updates and new features, potentially hindering the adoption of cutting-edge technologies.

Conversely, commercial CAM software is renowned for its comprehensive support and regular updates. Users benefit from dedicated customer service teams, which can be crucial for troubleshooting and optimizing software performance. Commercial solutions often come with extensive documentation and training resources, facilitating smoother implementation and user onboarding. Additionally, these platforms tend to offer more advanced features and integrations, which can enhance productivity and efficiency.

Nevertheless, the cost associated with commercial CAM software can be a significant consideration. Licensing fees and subscription models can impose a substantial financial burden, especially on smaller enterprises. Additionally, commercial software may offer limited flexibility compared to open-source alternatives, as users are restricted to the functionalities provided by the vendor.

Ultimately, the choice between open-source and commercial CAM software hinges on the specific needs and resources of the user. For those prioritizing cost and customizability, open-source options may be the best CAM software. Conversely, users seeking robust support and advanced features might find commercial solutions more suitable.

Cost-Effective CAM Software Solutions

For small businesses and startups, the financial aspect of implementing CAM software can be a significant concern. However, the market offers a range of cost-effective CAM software solutions that cater to budget-conscious manufacturers. Identifying the best CAM software that balances affordability and functionality is crucial for these enterprises.

Among the most accessible options are free CAM software packages, which are ideal for small-scale operations and educational purposes. Programs like FreeCAD and Fusion 360 (which provides a free license for startups and hobbyists) offer robust features at no cost. FreeCAD, for example, is an open-source platform that supports parametric modeling and is equipped with a suite of tools for design and simulation. Fusion 360, while primarily known for its CAD capabilities, also includes comprehensive CAM features, making it a versatile choice for cost-sensitive projects.

For businesses that can allocate a modest budget towards software but need more advanced capabilities, low-cost CAM software options are available. Software such as SolidCAM, BobCAD-CAM, and RhinoCAM provides powerful functionalities at a fraction of the cost of high-end solutions. These programs often offer tiered pricing structures, enabling users to select packages that best fit their specific needs and financial constraints. For instance, RhinoCAM integrates seamlessly with Rhino 3D, providing a robust CAM solution for intricate design and manufacturing tasks at a competitive price point.

To maximize value while minimizing costs, manufacturers should consider strategies such as subscribing to cloud-based CAM software, which tends to be more affordable due to its subscription model. Another effective approach is to leverage community forums and online tutorials, which can provide valuable insights and troubleshooting advice without the need for expensive support contracts.

Ultimately, the best CAM software for a small business or startup is one that offers the right mix of affordability, functionality, and scalability. By carefully evaluating available options and employing strategic cost-saving measures, manufacturers can effectively integrate CAM software into their operations without compromising on quality or performance.

Customer Reviews and Testimonials

User feedback plays a crucial role in evaluating the best CAM software. Insights from professionals and businesses who rely on these tools daily can significantly influence decision-making for potential users. Below, we have compiled a range of reviews and testimonials to provide a comprehensive understanding of the reliability and performance of different CAM software options.

One widely respected software, Fusion 360, receives high praise for its intuitive interface and robust functionality. A mechanical engineer from a mid-sized manufacturing firm commented, “Fusion 360 has revolutionized our workflow. Its cloud-based platform allows for seamless collaboration, and the precision of its CAM capabilities is unparalleled.” The software boasts an average rating of 4.5 out of 5 stars from over 1,000 reviews, reflecting strong user satisfaction.

Similarly, Mastercam is lauded for its advanced toolpath options and comprehensive support. A senior CNC programmer remarked, “Mastercam’s efficiency in handling complex geometries and its extensive library of machining strategies make it indispensable. The technical support team is also highly responsive, which is critical for our operations.” Industry experts give Mastercam a rating of 4.7 out of 5, underscoring its reliability in demanding environments.

On the other hand, SolidCAM receives accolades for its tight integration with SolidWorks. A design engineer highlighted, “SolidCAM’s integration with SolidWorks streamlines our design-to-manufacture process. The real-time simulation and extensive post-processing options have minimized our trial-and-error phase, boosting overall productivity.” SolidCAM maintains an average rating of 4.6 out of 5, with many users emphasizing its seamless workflow integration.

While these examples highlight some of the best CAM software options available, it is essential to consider specific needs and preferences. User reviews and expert ratings provide invaluable insights, but the ultimate choice should align with the unique requirements of each manufacturing operation. By leveraging the experiences of seasoned professionals, potential users can make informed decisions that enhance their manufacturing efficiency and effectiveness.

Educational Resources and Training for CAM Software

Continuous learning is indispensable in the rapidly evolving field of CAM software. To stay abreast of the latest advancements and best practices, professionals have access to a myriad of educational resources and training opportunities. A variety of online courses and certifications are available, often provided by leading institutions and CAM software developers. Notable platforms such as Coursera, Udemy, and edX offer comprehensive courses covering both fundamental and advanced aspects of CAM software. These courses are designed to cater to different proficiency levels, from beginners to seasoned experts, ensuring that there is something for everyone.

Workshops, webinars, and seminars also play an integral role in professional development. These events are frequently organized by software vendors and industry associations, providing hands-on experience and direct interaction with experts. Attending these events is an excellent way to gain practical skills, network with peers, and stay updated on the latest trends and innovations in CAM software. Additionally, many of these sessions are now available online, offering greater flexibility and accessibility to participants worldwide.

For those who prefer traditional learning methods, a wealth of books on CAM software is available. Titles such as “Mastering CAD/CAM” by Ibrahim Zeid and “Computer-Aided Manufacturing” by Chang, Wysk, and Wang offer in-depth knowledge and practical insights. These books are valuable resources for understanding the theoretical underpinnings and practical applications of the best CAM software.

Blogs and forums also serve as dynamic platforms for ongoing education. Websites like CNC Cookbook and Practical Machinist provide a steady stream of articles, tutorials, and user discussions. Engaging with these communities allows users to share experiences, troubleshoot issues, and exchange tips on maximizing the efficiency of their CAM software. Regular participation in these forums can significantly enhance one’s understanding and proficiency.

In conclusion, the abundance of educational resources available ensures that CAM software users can continuously enhance their skills and knowledge. By leveraging online courses, attending workshops, reading authoritative books, and engaging in active online communities, professionals can stay competitive and proficient in the ever-evolving landscape of CAM software.

CAM Software Integration and Workflow

Integrating CAM software with existing systems is a crucial step towards enhancing the efficiency of manufacturing processes. A seamless integration can significantly streamline workflows, enabling smoother operations and better resource management. The first step in effective integration is to select the best CAM software that is compatible with the current IT infrastructure. Compatibility ensures minimal disruptions and smoother transitions during the implementation phase.

Once the appropriate CAM software is chosen, it is essential to map out the current workflow. Understanding the existing processes allows for identifying areas where the CAM software can introduce improvements. For instance, automating repetitive tasks, reducing manual errors, and improving the precision of manufacturing operations are some of the benefits that come with a well-integrated CAM system.

To streamline workflows, it is advisable to focus on data centralization. Centralized data management allows for real-time updates and consistent information flow across various departments. This ensures that all teams are on the same page, thus reducing delays and enhancing coordination. Additionally, integrating CAM software with other enterprise systems such as ERP (Enterprise Resource Planning) and PLM (Product Lifecycle Management) can further optimize the workflow. This integration allows for better planning, scheduling, and tracking of manufacturing activities.

Best practices for using CAM software in a manufacturing environment include regular training for staff to ensure they are proficient in using the new system. Continuous learning and upskilling are vital as technology evolves. Moreover, maintaining a close collaboration between IT and manufacturing teams can help in quickly resolving any integration issues that may arise. Regularly updating the CAM software to the latest version is also crucial for leveraging new features and security enhancements.

Efficient integration and optimized workflows can significantly boost productivity and reduce costs. By following these guidelines and employing the best CAM software, manufacturers can achieve a more streamlined and efficient production process, ultimately leading to better product quality and faster time-to-market.

Troubleshooting and Support for CAM Software

Even the best cam software can face occasional issues that may hinder productivity. Understanding common problems and knowing how to troubleshoot them effectively is essential for maintaining smooth operations. One frequent issue users encounter is software crashes, which can often be resolved by ensuring that the system meets the software’s hardware and software requirements. Regularly updating both the operating system and the CAM software to the latest versions can also prevent compatibility issues.

Another common problem is incorrect toolpath generation. This can be due to several factors, including errors in the CAD model or incorrect parameter settings within the CAM software. Users should double-check their CAD designs for any flaws and verify that all toolpath parameters are correctly set according to the material and machine specifications. Moreover, using simulation features available in most CAM software can help identify potential issues before actual machining begins.

Licensing issues can also disrupt workflow. Users should ensure that their software licenses are up-to-date and properly activated. If the software uses a network license, checking the server status and network connectivity can often resolve related problems. In cases where the license file becomes corrupted, contacting the software provider for a replacement is recommended.

For more complex issues, leveraging the resources provided by the CAM software community can be invaluable. Many CAM software providers offer extensive documentation, including user manuals, FAQs, and troubleshooting guides on their official websites. Online forums and user groups can also be excellent places to seek advice from experienced users who may have faced and resolved similar issues.

When self-help resources are insufficient, reaching out to the software provider’s technical support team is crucial. Most reputable CAM software vendors offer multiple support channels, including phone, email, and live chat. Maintaining a service contract with the provider can ensure access to timely and expert assistance, minimizing downtime and keeping manufacturing processes on track.

Leave a Comment