Navigating the world of CNC lathe machines can be a complex journey, especially when one tries to balance quality with affordability. The CNC lathe machine price varies widely, influenced by factors such as brand reputation, precision level, and additional features. Understanding the cost dynamics is crucial for businesses and hobbyists alike to make informed decisions that align with their operational needs and budget constraints. The quest for the best deals on these machines underscores the importance of diligent research and comparison shopping.

In our guide, we delve into the factors affecting CNC lathe machine prices, providing a clearer picture of what drives cost variations in the market. We explore popular brands and their pricing strategies, offering insights into what you can expect to spend. From entry-level to high-end CNC lathe machines, we compare various models to help you identify the best value for your investment. Additionally, we discuss the advantages of buying from different sources and outline cost considerations for different types of machines. By the end of this article, you’ll be equipped with the knowledge to secure the best deals on CNC lathe machines, ensuring you make a purchase that meets both your quality standards and budgetary constraints.

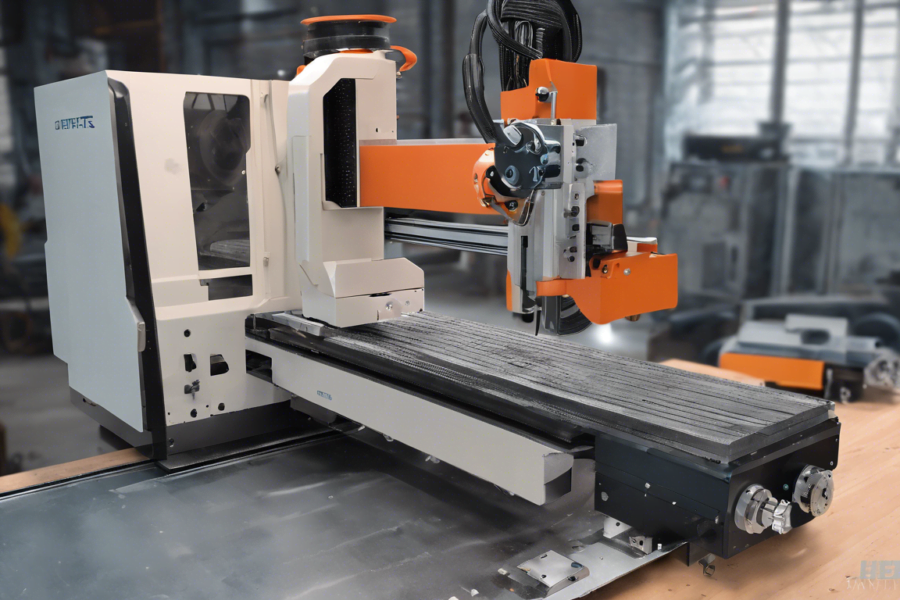

Factors Affecting CNC Lathe Machine Prices

Understanding the factors that influence the price of CNC lathe machines is critical for anyone looking to invest in this technology. Prices can vary widely based on several key aspects, each contributing differently to the overall cost.

Machine Type and Specifications

The type of CNC lathe machine you choose significantly impacts the price. Machines designed for specific tasks like metalworking often carry a higher price tag due to their specialized capabilities. Additionally, the size and capacity of the machine play a crucial role; larger machines capable of handling bigger workpieces are generally more expensive. This is due to the increased material, components, and complexity involved in their construction. Moreover, machines with higher precision and cutting abilities also tend to cost more due to the advanced technology required to achieve such specifications.

Brand and Manufacturer

The brand and quality of the manufacturer are pivotal in determining the price of CNC lathe machines. Established brands usually offer machines at a premium due to their market reputation, reliability, and the after-sales support they provide. It’s important to assess the manufacturer’s reputation because well-known brands might offer better durability and customer service, which can be worth the extra cost in the long run.

New vs. Used Machines

Choosing between new and used CNC machines can significantly affect the price. New machines come with the latest technology, full warranties, and support from the manufacturer, making them more expensive but also more reliable. On the other hand, used machines are less costly and can be a great option for those on a tight budget or businesses just starting out. However, potential buyers must be cautious about the machine’s condition and the availability of parts and service, which can add to long-term costs.

Additional Features and Customization

The price of CNC lathe machines can also escalate with the addition of optional features and customization. Features such as automatic tool changers, coolant systems, and sophisticated software packages represent advanced technology that can enhance performance but also add to the cost. Customization options allow machines to be tailored to specific needs, but this flexibility comes at a premium. It’s essential to consider which features are necessary for your operations and whether they justify the additional expense.

In summary, several factors affect the cost of CNC lathe machines, from the type and specifications of the machine to the brand and additional features. By carefully considering these factors, you can make a more informed decision that balances cost with functionality, ensuring you invest in a machine that meets your specific needs without overspending.

Popular Brands and Their Pricing

Exploring the landscape of CNC lathe machines, it’s essential to understand the pricing and offerings of popular brands such as Haas, Doosan, Mori Seiki, Mazak, and Okuma. Each of these brands has carved a niche in the market, providing unique features and benefits that cater to various machining needs.

Haas

Haas Automation is renowned for its comprehensive range of CNC machines, including their CNC lathes. Known for their reliability and affordability, Haas machines are a popular choice among small job shops and large manufacturers alike. The brand has been a significant player since 1988, offering machines like the VF-1 vertical machining center which was introduced at less than $50,000. Today, Haas continues to offer a variety of machines at competitive prices, with CNC lathes starting around $40,000, going up to several hundred thousand dollars for more advanced models.

Doosan

Formerly known as Daewoo, Doosan acquired Daewoo’s machinery segment in the early 2000s and has since been known as a robust manufacturer of CNC lathes and turning centers. Doosan’s machine tools, including the popular Puma series, are celebrated for their high-speed capabilities and heavy-duty performance. The pricing for Doosan CNC lathes varies depending on the model and specifications, with a strong presence in both the new and used equipment markets.

Mori Seiki

Mori Seiki, now part of DMG Mori, offers a range of CNC lathes that are highly regarded for their precision and reliability. The brand has a rich history of innovation and quality, with models like the NLX and NT series that cater to high-precision machining needs. Mori Seiki machines are typically positioned at a higher price point, reflecting their advanced technology and the extensive support network provided by DMG Mori.

Mazak

With over 100 years of manufacturing experience, Mazak stands out for its high-quality, innovative CNC solutions. Mazak’s CNC lathes are known for their robust construction and precision engineering, often coming at a premium price compared to competitors like Haas. Mazak machines are particularly favored for tight-tolerance work and their ability to handle tough materials, making them a preferred choice in industries requiring utmost precision and durability.

Okuma

Okuma is acclaimed for its high-quality and affordable CNC lathes, like the GENOS series, which combine excellent performance with cost-efficiency. The brand’s approach to accessible pricing allows smaller shops to adopt advanced machining capabilities without a significant financial burden. Okuma’s pricing strategy focuses on providing value at every level, ensuring that even entry-level models like the GENOS L400II offer superior stability and accuracy.

By understanding the offerings and pricing strategies of these key players, we can better navigate the complex market of CNC lathe machines, ensuring that we choose a machine that not only fits our budget but also meets our specific manufacturing needs.

Comparison of Entry-Level CNC Lathe Machines

When we explore the realm of entry-level CNC lathe machines, we’re looking at options that are not only accessible in terms of cost but also provide a gateway to CNC machining for beginners and small businesses. Here, we’ll dive into the specifications, pricing, and the pros and cons of these machines, focusing specifically on models like the Taig and Sherline, which are popular in this category.

Specifications

Entry-level 2-axis CNC lathes, such as those offered by Taig and Sherline, are priced under $5,000. These machines are typically smaller in size and less complex than their more expensive counterparts. They are designed to handle basic machining tasks and are ideal for learning the fundamentals of CNC operations. The simplicity of these 2-axis lathes makes them suitable for small-scale production and hobbyist projects.

Pricing

The pricing for entry-level CNC lathes is quite attractive, making them accessible to a broader audience. For instance, you can find entry-level desktop CNC routers starting as low as $150 to $500. Hobby level CNC routers and CO2 lasers range from $1,000 to $3,000, providing more power and versatility than the most basic models. These price points make CNC technology reachable for individuals and small businesses, allowing them to engage in precise machining without a significant initial investment.

Pros and Cons

The benefits of opting for an entry-level CNC lathe machine include lower cost and reduced floor space requirements. These machines are typically easier to install and maintain, with less complexity in their design and operation. They are perfect for those just starting out or those who need a machine for occasional, less complex tasks.

However, there are drawbacks to consider. Entry-level machines may not offer the same rigidity, accuracy, or durability as higher-end models. They can be prone to more frequent repairs and quicker wear and tear. Additionally, these machines may not support advanced features like multiple axes of motion or built-in automation, which can limit their ability to perform more complex tasks. Users may also find that these machines do not always conform to modern programming methods, which could be a limitation for certain applications.

In conclusion, while entry-level CNC lathes offer a cost-effective entry point into CNC machining, it’s crucial to assess whether their capabilities align with your machining needs. Consider the trade-offs between price and performance to ensure that the machine you choose can adequately handle the tasks you plan to undertake.

Mid-Range CNC Lathe Machines

When we delve into mid-range CNC lathe machines, we’re examining models that typically cost between $30,000 and $100,000. These machines strike a balance between affordability and advanced capabilities, making them suitable for more complex turning tasks and versatile enough for a variety of applications.

Specifications

Mid-range CNC lathe machines are designed to offer more than just basic functionalities. They often come equipped with features that allow for both increased precision and versatility. For instance, many mid-range models can handle larger and more complex parts compared to entry-level machines, thanks to their enhanced rigidity and stability. These machines might include options like live tooling, C-axis capabilities, and Y-axis functionalities, which are essential for performing intricate machining operations. The specifications can vary widely, but typical features might include spindle sizes ranging from 6.5 inches to 18 inches, bar capacities from 1.75 inches to 12.5 inches, and power outputs from 15 to 55 HP, depending on the model.

Pricing

The pricing for mid-range CNC lathe machines reflects their enhanced capabilities. With prices ranging from $30,000 to $100,000, these machines represent a significant investment for most businesses. However, the cost is justified by their increased functionality and the ability to handle more complex projects that go beyond the capabilities of lower-end machines. Brands like Haas offer a variety of options within this range, including dual-spindle models and toolroom lathes, which provide the flexibility to choose a machine that best fits the specific needs of a business.

Pros and Cons

The advantages of opting for a mid-range CNC lathe machine include the ability to perform a wider range of machining tasks with greater precision and efficiency. These machines are typically more robust, offering better performance and durability, which is crucial for businesses aiming to increase their production capabilities. Additionally, the availability of advanced features like multi-axis capabilities and live tooling allows for the production of complex parts without the need for multiple setups.

However, there are also considerations to keep in mind. The higher cost of these machines can be a significant barrier for smaller shops or startups. Moreover, the complexity of these machines means they require skilled operators and more sophisticated maintenance, potentially increasing operational costs. It’s also important to consider the space requirements, as mid-range machines generally have a larger footprint than entry-level models.

In choosing a mid-range CNC lathe machine, we must weigh these pros and cons carefully. The decision should align with the specific production needs and budget constraints of our operations, ensuring that the investment not only enhances our machining capabilities but also contributes positively to our overall business objectives.

High-End CNC Lathe Machines

Specifications

High-end CNC lathe machines, priced between $100,000 and $500,000, are the pinnacle of precision and versatility in the machining world. These machines often cater to specialized industries such as aerospace and automotive, where the demand for precision is paramount. The capabilities of these machines include multi-axis machining centers that allow for intricate and complex part designs that lesser machines could not handle efficiently. The size of these machines can vary significantly, often determined by the types of parts being manufactured. Larger machines, necessary for producing big or complex parts, are inherently more expensive due to the increased amount of material and components required, as well as the complexity involved in their manufacturing.

Pricing

When considering the investment in a high-end CNC lathe machine, prices can range dramatically from $100,000 to several million dollars. This variance is influenced by several factors including the machine’s power, size, and the specific technologies it incorporates. For instance, machines equipped with high-speed capabilities and advanced control systems like those from Fanuc or Mitsubishi are priced higher due to their enhanced productivity and precision. Additionally, machines that can handle a diverse range of materials—from metals to plastics and woods—are typically more costly. The brand and reputation of the manufacturer also play a crucial role in pricing, with well-known brands commanding higher prices due to their proven reliability and extensive support services.

Pros and Cons

The advantages of high-end CNC lathe machines are numerous. They offer unparalleled consistency, producing parts with high precision time after time, which is crucial for industries requiring exact specifications. The technology embedded in these machines allows for designs that are impossible to achieve manually, and the software can be updated to enhance performance continually. Moreover, the ability to run these machines continuously for extended periods reduces downtime and increases productivity. However, the initial cost is a significant consideration, as these machines represent a substantial financial investment. Additionally, the complexity of these machines requires operators to have specialized training, and the maintenance can be more involved compared to lower-end models. Despite these cons, the long-term benefits and the potential for increased production often justify the initial high cost for many businesses.

By carefully weighing these specifications, pricing details, and pros and cons, we can make informed decisions that align with both our operational needs and financial capabilities, ensuring that the investment into a high-end CNC lathe machine is both prudent and beneficial.

Buying from Different Sources

When exploring the purchase of CNC lathe machines, the source from which you buy can significantly impact both the price and the quality of the equipment. Each source, whether it’s dealers, direct from the manufacturer, online platforms, or auctions, offers unique advantages and considerations.

Dealers

Buying from dealers is a traditional and reliable method. Many dealers have a strong relationship with manufacturers and often have access to a broader range of products. Dealers can provide valuable pre-sales advice and after-sales support. However, prices might be slightly higher due to the middleman’s role. It’s crucial to choose reputable dealers who are known for quality and reliability. Our experience shows that dealers often cater to both end-users and other dealers, suggesting a versatile customer base that benefits from their comprehensive service and product knowledge.

Direct from Manufacturer

Purchasing directly from the manufacturer is another viable option. This route often allows for customization of the CNC machine to your specific needs and might offer lower prices by eliminating the dealer’s markup. However, it requires a good understanding of your requirements, as manufacturers typically offer less guidance than dealers. Direct purchases can be advantageous for those who have precise specifications and are looking for the newest models available.

Online Platforms

The rise of digital technology has made online platforms a popular choice for buying CNC parts and machines. Online stores are accessible 24/7, offering convenience and the ability to quickly compare prices across multiple vendors. Websites like Tradewheel and Made-in-China provide a vast selection of products and competitive pricing due to their large scale and low overhead costs. Additionally, online platforms often feature customer reviews and detailed product descriptions, which can help in making an informed decision.

Auctions

Auctions can be a source of excellent deals, particularly for used machinery. They offer the opportunity to purchase equipment at potentially lower prices than the market rate. However, it’s important to have a clear understanding of the auction terms and the condition of the machinery being sold. Companies like Resell CNC have received positive feedback for their customer service and reliability in handling auction sales. They ensure a professional experience by providing detailed information about the machines and facilitating smooth transactions.

Each of these sources has its merits and potential drawbacks. We recommend assessing your specific needs, budget, and the level of support you require before deciding on the best source for purchasing a CNC lathe machine.

Cost Considerations for Different Machine Types

When considering the purchase of CNC lathe machines, it’s essential to understand how different machine types, configurations, and tooling options impact overall costs. This section explores the cost considerations for various machine types, focusing on Horizontal vs. Vertical, 5-Axis vs. 3-Axis, and Turret vs. Gang Tooling.

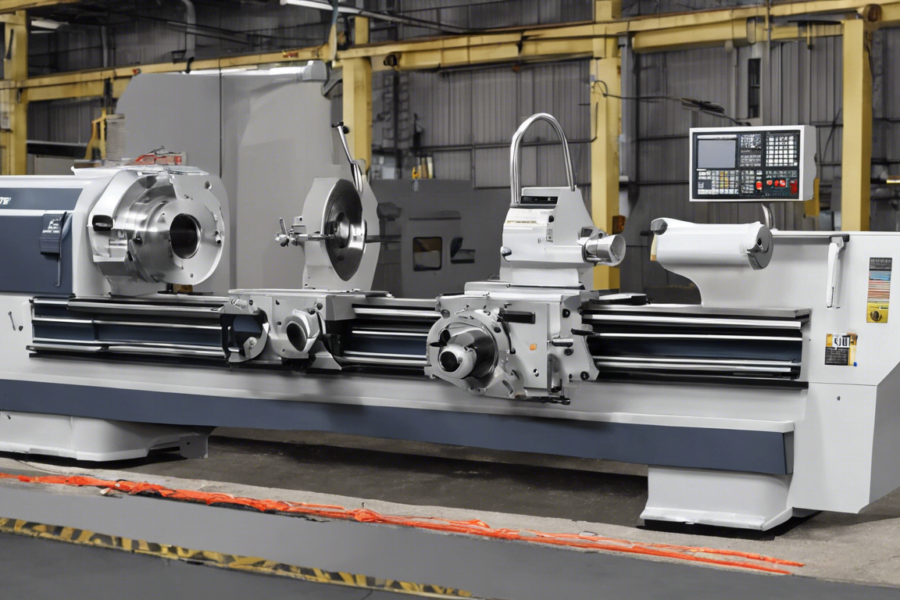

Horizontal vs. Vertical

Horizontal machining centers (HMCs) are typically more complex and costly compared to vertical machining centers (VMCs). The complexity of HMCs, often equipped with features like pallet changers and multiple spindles, translates into a higher price point, reflecting increased productivity capabilities. On the other hand, VMCs generally have lower upfront costs and occupy less floor space, making them a more economical choice for operations that do not require the advanced features of HMCs. The decision between these two types should consider the specific production requirements and available space.

5-Axis vs. 3-Axis

The choice between 5-axis and 3-axis CNC machines significantly affects both the initial investment and ongoing operational costs. 5-axis machines, known for their advanced features and capabilities, are considerably more expensive, with prices ranging from $80,000 to over $500,000. These machines facilitate complex geometries and multi-sided machining without manual repositioning, leading to higher accuracy and reduced setup time. However, they also require higher maintenance and operational expertise. In contrast, 3-axis machines are more budget-friendly, ranging from $25,000 to $50,000, and are easier to program and maintain. They are suitable for simpler, flat-surface jobs, making them a better starter investment for small businesses or those with limited CNC machining needs.

Turret vs. Gang Tooling

The choice between turret and gang tooling also influences cost considerations. Turret tooling, characterized by its ability to house multiple tools, offers greater flexibility and is better suited for complex parts and operations. However, its complex construction with many moving parts makes it more expensive and potentially more prone to maintenance issues. Gang tooling, with its simpler and more robust design, offers quicker tool changes and reduced tolerance stack-up, leading to higher precision. It is generally more cost-effective and provides faster setup times, although it requires careful programming to avoid tool crashes. Gang tooling is ideal for dedicated, long-run jobs where cycle time optimization is crucial.

Each of these configurations presents unique advantages and challenges, impacting the total cost of ownership and operational efficiency. By carefully considering these factors, businesses can select the machine type and tooling that best fits their production needs and budget constraints, ensuring a balance between cost and functionality.

Venturing through the diverse and intricate world of CNC lathe machines, our exploration reveals a nuanced landscape of pricing dynamics, shaped by type, specifications, brand reputation, and additional features. This guide has endeavored to illuminate the path for both novices and seasoned machinists alike, offering insights into making informed decisions that harmonize with their operational requisites and fiscal frameworks. By dissecting the spectrum from entry-level to high-end machines, we have strived to underscore the pivotal considerations that come into play when investing in such technology, emphasizing the balance between cost, functionality, and the broader implications of machine type selection on production capabilities and budget allocations.

As we conclude, let us reiterate the importance of aligning one’s purchase with both current needs and prospective endeavors, ensuring that the choice of a CNC lathe machine enhances machining capabilities without overshooting budgetary boundaries. The journey doesn’t end with the acquisition; it’s a continuous evolution of adapting to technological advancements, optimizing operational processes, and possibly, exploring further avenues for research or action based on the acquired equipment. Reflecting on the insights presented, the decision to invest in a CNC lathe machine — be it from dealers, directly from manufacturers, through online platforms, or auctions — demands a well-rounded comprehension of the machines’ specifications, capabilities, and the strategic objectives they are intended to fulfill.

FAQs

1. What is the typical price range for a new CNC lathe?

CNC lathes come in various price ranges, depending on their capabilities and features. Mid-range CNC lathes, which offer versatility for more complex turning tasks, are generally priced between $30,000 and $100,000. High-end models, known for their superior precision and versatility, can cost anywhere from $100,000 to $500,000.

2. How long can a CNC lathe be expected to operate?

The lifespan of a CNC lathe depends on several factors, including the type and quality of the machine and the frequency of its use. With proper maintenance, a CNC lathe can typically last anywhere from 10 to 20 years, though many last even longer.

3. What type of CNC lathe is most commonly used in the industry?

The most commonly used type of CNC lathe is the Horizontal CNC Lathe. This machine is primarily used for turning and boring operations and is a popular choice in the industry due to its efficiency and versatility.

4. Which brands are considered the best for CNC machines?

Several brands are renowned for their high-quality CNC machines, including:

- Yamazaki Mazak (Japan)

- Trumpf (Germany)

- DMG MORI (Germany + Japan)

- MAG (USA)

- Haas (USA)

- Hardinge (USA)

- AMADA (Japan)

- Okuma (Japan) These manufacturers are known globally for their advanced technology and reliable products.

Leave a Comment